Extraction of Oil from Groundnut Seed

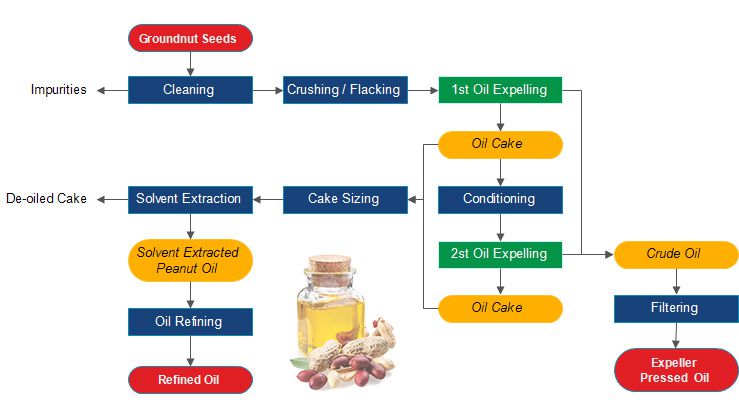

When it comes to the extraction of oil from groundnut seed, there are two common oil extraction process: cold press and hot press. In order to improve the oil yield, hot press is usually adopted.

Hot Pressing Process: Peanut kernel → cleaning → crushing → cooking / steaming→ oil pressing → filtering → expeller pressed peanut oil

Groundnut is a kind of oil with high oil content. The residual oil in oilcake can be reduced to 6.5% by second pressing. The temperature of the whole process of cold pressing is required to be below 60℃, so that to guarantee the quality of cold pressed oil.

Project Display: Complete Groundnut Oil Extraction Plant

TOP Quality, BEST Price, Great Service!

Groudnut Oil Mill Plant Setup

Groundnut Oil Factory Layout Design

ABC Machinery - reliable groundnut oil extraction machine manufacturer, offer high quality oil extraction machines and turnkey customized oil processing plant for all kinds of oilseeds and nuts.

Groundnut Oil Extraction Process

The followings are an overview of groundnut oil extraction technologies. Feel free to send us an inquiry to one-to-one service on customized process design, equipment selection, factory layout and cost details!

Complete Peanut Oil Extraction Process for Reference

- Shelling

For the peanut with shell, shelling is needed to improve the oil production capacity and oil yield. Its supporting equipment is: peanut sheller and screen sieve.

- Seeds Cleaning

The purchased groundnut kernels generally contain some impurities. Without cleaning, the impurities will not only affect the quality of produced oil and oilcake, but also can adsorb part of oil to decrease the oil yield. If there are sand, metal, hemp rope and other sundries in the peanut, it will cause wear and tear on the parts, even inducing production. The impurity content of the cleaned groundnut kernels should not exceed 0.2%。There are many cleaning methods. Different methods can be used according to the condition of impurity. If the impurities are light, such as grass, stem and leaves, wind selection method can be used to blow off the impurities with airflow. If there are iron impurities, electromagnet or permanent magnet can be used.

- Seeds Crushing

Large oilseeds must be crushed before being tempered. The purpose of crushing is to increase the surface area of the oil to facilitate the transfer of temperature and water, so as to improve the oil yield. The particle size after cracking should be 6-8 pieces. In order to meet the requirements of crushing, it is necessary to control the moisture content of seeds 7%~12%.

- Heating (Steaming / Cooking)

Heat treatment is one of the important processes in groundnut oil extraction plant. The effect of heat treatment has a direct effect on the whole oil production process, oil yield, oil and oilcake quality.

- Oil Extraction (expelling / squeezing)

Multifunction Peanut Oil Machine for Earth Nut / Peanut

The well processed groundnut kernels are fed from the hopper into the oil press chamber. The kernels are continuously pressed by the squeezing spiral. Screw type groundnut oil manufacturing machine is the main equipment used in small to medium scale edible oil extraction plant, featured of reasonable structure design, high pressure and low labor intensity.

Main Features of Our Multifunction Groundnut Oil Extraction Machines

The main components of screw type peanut oil expeller include a speed reduction gear, a drain collector, pulleys and a hopper. The machine is driven by electric motor. One of the most unique feature is that it assembles oil expeller, electric heatting pipe and vacuum oil filter press together. It is characterised by a high rate of oil output and great oil quality. There are a plenty of benefits of this multifunction oil making machines, making it worth buying for oil production business owners. The vital ones are listed out here for your easy understanding: cost-effective, affortable for farmers and small oil milling workshops; easy operation and maintenance, low noise; cover a small area, etc.

Preparation of Groundnut Oil Extraction Machine before Starting Up

- Fill the gearbox with 10kg oil before starting up.

- Tighten each screw and nut to check whether the above parts are loose or damaged. Fill lubricating oil, turn the pulley to see if it is flexible, and carefully check whether there is collision between the parts.

- Adjust the clearance between the screw shaft and the press ring before starting up the groundnut oil making machine. The method is to push the screw shaft forward to the press ring, and then go back 2-4 laps.

- After the above check and adjustment, run the machine to idle for 5 minutes to see whether there are any exceptions such as collision and death. When you confirm that the machine is running completely normal, you can feed the pre-processed oilseeds materials in.

- Appropriate temperature of oil pressing chamber will have good oil extraction effect, so the chamber temperature should be raised before formal oil production.

- Groundnut Oil Refining

Refined oil and unrefined oil: Unrefined groundnut oil has a nutty taste, making it an ideal choice for salad dressings. Refined peanut oil is produced after bleaching and deodorization in cooking oil refinery plant, used as an attractive frying oil. During the refining process, the components that might cause peanut-based allergies are also removed, non-allergic. (Related Post: Peanut Oil Cold Filteration Machine)

Complete Set of Peanut Oil Refinery Machine (1-10ton/d)

Now that you have a fair idea about groundnut oil extraction machine and refinery machine, you must have understood how important and best suited equipment is for your oil manufacturing business. With the help of ABC Machinery, you will be able to get a boost to your business which will help you to produce high-quality cooking oil in short time with less effort, and make more money. So what are you waiting for? Send us an inquiry to get more details of our groundnut oil extraction machine right now!

Groundnut Oil Production Market Profile

Groundnut is native to Latin America and some other tropical regions. Groundnut or peanut oil is one of the most common vegetable oils for cooking or enhance the food flavor. It can be segmented on the basis of type, application, and packaging.

| Peanut Oil Production Annual Growth Rate by Country (Year of Estimate: 2019) | |

|---|---|

| Senegal | 20.00 % |

| United States | 7.07 % |

| Burkina Faso | 5.26 % |

| India | 3.21 % |

| China | 2.79 % |

Different Application: Groundnut oil is mainly applied in market of food, pharmaceutical, personal care products and others. Food industry (including oil extraction) is the main application field, and is expected to remain so due to the nature of the market. Groundnut oil is not only rich in protein content but is equally very tasty and edible. In India the oil is further processed to produce margarine as well as soaps, paints and cosmetics. Almost fifty percent oil can be extracted from groundnuts.

Different Packaging: The produced oil can be packed in plastic bottles and containers, plastic pouches and glass containers. If you are planning to start your own groundnut oil manufacturing business, you should select the kind of packaging method depending on convenience, cost and shelf life.

Regional Outlook of Peanut Oil Business

India and China is the main groundnut oil producer, and account for over 50% of the global production. The United States is also a major producer of peanut oil with over 10% of the global share. On the basis of consumption, the market presents a more complex and region-specific trend. The overall observable trend being that the increase in consumption is closely related to the increasing incorporation of peanut oil in food products.

-

Hello

I have ground nut oil mill plant . but I want to update my mill plant for soyabeen so i need your help . - What's the capacity of your current ground nut oil mill plant? and what's your desired processing capacity for your soybean oil mill plant?

- I am interested in the corn and groundnut oil extracting machine mail full detail for me.

-

Is the groundnut dehulled or not?what's your capacity per day and how many hours do your work per day?

As for corn, we could only press oil from corn germ, not corn! pls confirm this soon! -

Sir,

Kindly send me a quotation of groundnut oil production machine with the capacity of 300 litres per hour. My peanut don't have shell. -

Thank you for your reply. According to your inquiry, you want near 300liters oil per hour, it's near 8ton per day. And according to the oil yield of the peanut kernel, you will need near 1ton peanut kernel per hour, that is to say your total capacity will be near 25ton per day.

So, pls confirm whether you need the oil refinery equipments and the filling machine or not? Besides, if convenient could you give me some information on your side, such as your telephone, then we can communicate more efficiently.

Questions pls tell me freely, waiting for your reply. -

Pls do you have 5 tons machineries for the groundnut oil processing and how much?

The price given for both 25tons and 10tons were above my project budget.

If you have machineries with 5 tons capacity , kindly send me the quotation so that I can go ahead and process the payment. -

We have the 5TPD machines for groundnuts.

As for the 5TPD capacity, I just equip three machines for you, they are the necessary machines for the small oil plant. Details pls check attachment.

I also equip the oil refinery equipments in the proposal, but if it's your first business and don't have so much budget, you also can choose to just order press equipments and the filling machine, then selling the crude oil. When you have the experience in this field, you can consider to install the refinery equipment.

To make you know more about our machines, I will send you one video for your reference, it's one project we just established in India. It's the 10TPD press workshop and the 1TPD oil refinery equipment, details pls check the email. -

Hello,I need a machine with about 8-20ton/day. it's will serve my purpose. I have the following questions on the Groundnut Oil Extraction Machine:

1. What is the cost of this Machine?

2. Do I need to roast the groundnut/soybeans before processing with Machine?

3. Does the Machine comes with the nut roaster?

Thank you. -

1. The detailed cost of this machine has been sent to your email.

2. Yes, it's better to roast the material before pressing, it could improve the oil yielding rate. if your raw material includes both groundnut and soybean, we suggest that you could have oil press and filter sperately. It's cheaper, besides, it's better to press raw material soybean.

3. No, the roaster is excluded in the machine, pls advise you capacity per day, so we could recommend for you, also look forward to hearing from you soon! -

Sir, what is the economic viability of ground nut oil and palm kernel oil in Nigeria which is higher and what is the cost of the machines?

Can I use the same machine (expeller and heater even refining line) for ground nut and palm kernel oil production?

Also how much is the machine? - Yes, you could use the same machine for pressing ground nut and palm kernel. Pls kindly advise how much raw material do you want to process per day, so we could design and quote for you accordingly soon.

-

Hi. I used to be in into groundnut oil production and I'm interested in going back to it. I noticed that the method of extraction stated on ur website does not include frying. what is the advantage of your "preparation process" over frying.

Secondly I'll like to purchase a 2ton per day capacity oil press and if your oil filter can remove the odour, I'd like to purchase one too. I'll appreciate a list of prices for these equipments . I anticipate ur time response. -

Hi, Thanks for your enquiry to our products. The process in our website does include frying, just we call it cooking.

FYI, we suggest our cusomter the following process flowchart when the capacity is not big:

Raw material-> decorticating-> cleaning-> cooking-> Pressing-> Filtering-> Crude oil-> Cleaned oil

As for 2T/D capacity, we suggest the following two parts:

1-. 2~3TPD pressing

2-. 1TPD refinery production line.

For Pressing line, the processing flowchart is as follows:

Groundnut-> Cleaning-> Cooking-> Pressing-> Filtering-> Crude groundnut oil.

While for the refinery flowchart:

You could choose either freezing&filtering, OR refining(degumming, deacidification, decoloring and deodorization)

TOP Quality, BEST Price, Great Service!

Build Your Future!

Build Your Future!