- Project Name: Vegetable Oil Plant

- Production Capacity: 100 ton per day (equipped with 4TPH Steam Boiler which using biomass pellet or coal)

- Factory Location: Taldykorgan city, Almaty region, Kazakhstan

- Oilseeds to be processed: Sunflower seeds and Soybean

- Production Process: Oil seeds storage, screening, stone removal, crushing, softening, flaking, steaming and cooking, oil pressing and filtering etc.

This is a complete sunflower oil processing factory built in Kazakhstan. The production output is 100 ton/day. It is designed to process both sunflower seeds and soybean at the same time. (Related Oil Mill Project: 10TPD Sunflower Oil Pressing and Refining Plant in Moldova)

Photo Display: Sunflower Oil Factory in Kazakhstan

What's the Cost of Setting Up the Sunflower Oil Factory?

The setup cost of this sunflower oil mill plant is around $500,000, which includes the equipment of 100ton/h oil production line, 4 ton/h steam boiler system, and installation and commissioning fee. Actually, each project is customized depends on the clients' specific situation and needs, which meas the cost depends on many differen factors.

- Capacity

- Process Design

- Processing Technology

- Machine Quality

- Other Factors

Video: Sunflower Oil Production Plant in Kazakhstan Under Construction

If you are planning to start your own sunflower oil making business and feel interested to get a customized project plan with detailed business plan and quotation list, welcome to get in touch with us!

Vegetable Oil Production in Kazakhstan

As a main grain producer of the world, Kazakhstan is improving the oilseeds production rapidly in recent years, especially sunflower seeds. About 60% of the area cultivated under oil crops are sunflower.

| 2018 Sunflower Oil Production by Country (1000 MT) | |

|---|---|

| 1. Ukraine | 6,235 |

| 2. Russian Federation | 4,750 |

| 3. EU-27 | 3,718 |

| 4. Argentina | 1,400 |

| 5. Turkey | 935 |

| 6. China | 717 |

| 7. South Africa | 285 |

| 8. Kazakhstan | 245 |

| 9. Serbia | 225 |

| 10. United States | 202 |

About 135 000 tons of vegetable oil is required annually in this country, amount to 9kg per inhabitant. Most Kazakh vegetable oil factory work for the domestic market, but it still can’t meet the increasing demand. Sunflower oil dominates the local edible oil market. About 70% of the edible oil needs in Kazakhstan are supplied by domestic production of sunflower oil. Other 30% of the domestic consumer demand is supported by importing from Russian and other countries. The monthly production of crude sunflower seed oil has reach to about 12,200 tons in 2018, and production of refined sunflower oil has amounted to 8,500 tons. (Related Project: 150 ton/day Sunflower Oil Manufacturing Plant in Russia)

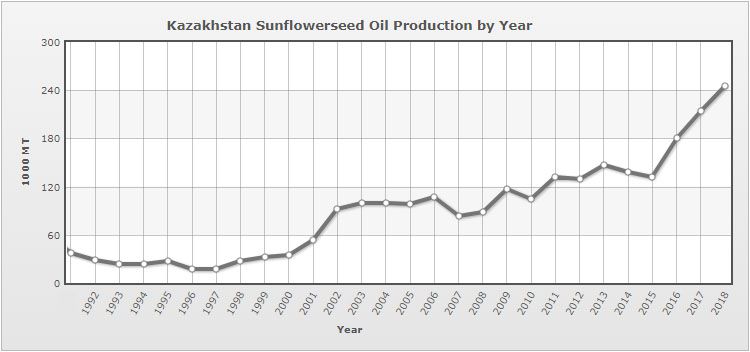

Kazakhstan Sunflower Seed Oil Production by Year

The vegetable oilseed processing industry of Kazakhstan has developed rapidly. There are about 303 vegetable oil processing companies and the annual output is up to 190 000 tonnes.

The edible oil consumption demand is growing rapidly year by year in Kazakhstan, and the demand exceeds domestic supply. As the major edible oil in the country, sunflower oil manufacturing plant is becoming a hot project to invest in.

New Opportunities of Establishing Sunflower Oil Factory in Kazakhstan

| Market Year | Sunflower Seed Oil Production (1000 MT) | Growth Rate |

|---|---|---|

| 2016 | 180 | 36.36 % |

| 2017 | 214 | 18.89 % |

| 2018 | 245 | 14.49 % |

Here let’s talk about the factors which promote the development of sunflower oil production industry and offers new opportunities of starting sunflower oil production plant:

- New Seeds are developed to Double Yields: New types of sunflower seed hybrids are used to double the sunflower yield.

- The area under sunflower is expanding: With the support of local policies, more and more farmers began to plant sunflowers. Aktobe for example, the area planted with sunflowers has increased fivefold in the past four years, from 5000 hectares to about 24000 hectares.

- Considerable Benefit: The competitive oilseed prices offered by local farmers have also added to appeal of setting up sunflower oil factories.

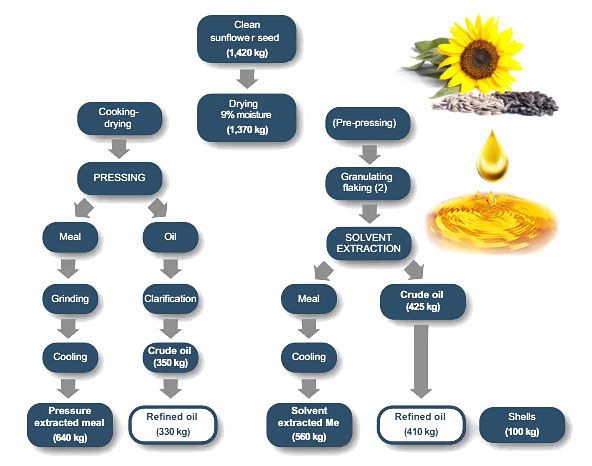

Technical Process of Sunflower Oil Manufacturing Factory

Sunflower Oil Manufacturing Process

- Cleaning

- Crushing

- Oil Pressing Process

- Solvent Extraction of Sunflower Seed Cake

- Removal of Solvent

- Refining the Sunflower Oil

Refining is usually the last process of edible oil plant and it involves the removal of colour, bitterness, and odor. At a temperature of 40-80 degrees and an alkaline substance such as sodium carbonate added. Degumming of the oil is done by heating at temperatures of between 85-95 degrees. This process precipitates most of the phosphates in the oil. Centrifugation process is done to remove the gums. To obtain pure oil eligible for cooking it is passed over heated carbon to remove pigmentation substances. Winterization is usually done to remove waxes so as to prevent solidification of the oil when in refrigerators.

Build Your Future!

Build Your Future!