Sunflower seed oil is widely used in industrial applications, such as paints, plastics, lubricants, exploration of diesel fuel, manufacturing of soaps and detergents, among others. But, most of the sunflower oil is used as an edible oil in form of salad cooking oil or margarine. Due to numerous uses, the demand of sunflower oil has increased to sustain the need. (Latest article: How to Start Sunflower Oil Factory >>)

Sunflower Seeds & Sunflower Oil

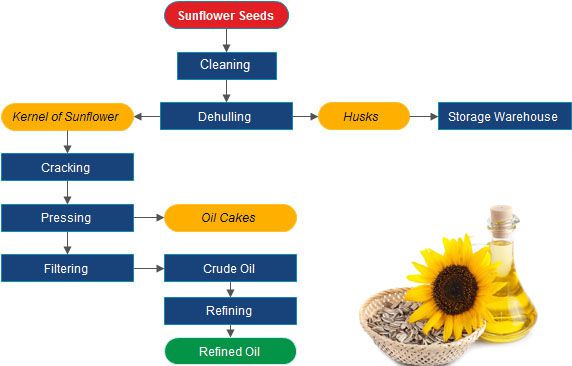

How is Sunflower Oil Processed?

The following is a systematic procedure regarding the oil processing practice within a sunflower oil processing plant.

- Sunflower Seeds Cleaning Preparation

The first thing to do is to prepare sunflower seeds for oil removal. This is done by cleaning to remove metallic substances using magnets. Then, screening is done to get rid of impurities that might affect the sunflower oil production process.

The first thing to do is to prepare sunflower seeds for oil removal. This is done by cleaning to remove metallic substances using magnets. Then, screening is done to get rid of impurities that might affect the sunflower oil production process.

- Seed De-hulling

This is done by crushing and removing the seeds’ shells before oil extraction to ensure the sunflower oil is of high quality. The crushed mixture is then winnowed to separate the hulls from kernels. This process is optional in case of some hard thin-hulled sunflower seeds in order to avoid oil loss. (Read more about Small Scale Sunflower Seed Dehuller >>)

- Seed Grinding

In this step, the de-hulled sunflower seeds are grounded using mechanized rollers or hammer mills to make a meal that is later heated for oil extraction. The purpose of grinding is to increase the surface area to be heated during extraction.

- Sunflower Oil Extraction

The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the slots in the barrel. This mechanical process almost removes half of the oil preceding the extraction of the solvent. (Read more about Sunflower Oil Extraction Machine for Sale)

- Crude Oil Extraction

In the extraction process, hexane and other solvents are used to dissolve the oil from the oil cake and maximize the output. The dissolved oil is then distilled to recover the oil, which is collected at the end of the process. The equipment is designed in different models to enhance the quantity of the solvent and the time taken in the oil processing.

- Solvent Traces’ Removal

A good percentage of solvent used after extracting the oil evaporates and is collected to be reused later in the extraction process. The residual solvent is stripped and recovered from the flakes using heat and steam. At this stage, you get desolvented fragments as final products and ready for market. The sunflower oil is further refined to a more edible product.

- Oil Refining

Refining is done to improve the color, flavor, odor, and stability by use of processes that enhance the bleaching, degumming, deodorizing and neutralizing the oil. This implicates heating the oil to around 40- 85 degrees Celsius and mixing it with carbonates or chlorides of sodium. The entire refining processes eliminate pollutants like free fatty acids, pro-oxidants, and phosphatides. Additional processing of fats and oils is often desirable. For instance, some are de-waxed while others are improved to alter their melting features. Now, you’ll get liquid and solid products which are then packed various quantities ready for market. The byproducts resulting from the entire process can be directly used or improved for extended use. (Read more about the Sunflower Oil Refining Plant Cost >>)

Above mentioned process is all about how the sunflower oil is processed. In actual operation, some of the process is custom made. This complete process is also avilable for other vegetable seeds and nuts, such as cottonseeds, peanut/groundnuts, palm kernel and more.

Small Scale Sunflower Oil Processing Line

Sunflower oil processing involves many process that will decide the equipment and machinery for a sunflower oil processing plant. For small scale sunflower oil processing line, the equipment may be relatively simple and easy to operate. Of course, the investment cost for small scale oil factory is low but the profits is considerable. If you are interested in the sunflower oil processing, please contact us for more detailed information!

Build Your Future!

Build Your Future!