Start Livestock Feed Production Business

- Project Name: Complete Set of Livestock Feed Production Line

- Production Output: 2 ton per hour

- Application: Can be widely applied to make feed for ruminant animals (sheep, goat, cattle, cow, horse, camel...).

- Main Equipment: Mixing machine, pellet mill, pellet cooler, bagging machine, belt conveyors and etc.

- Similar Project: 1 ton/h Mini Feed Mill Plant for Sale

Livestock Feed Production Equipment Details

This ruminant animal feed processing line is designed with flat die feed pellet mill. This combination unit of livestock feed production equipment aims to manufacture feed pellets for cud chewer and herbivorous animals. (Read more: Small Feed Pellet Machine Price >>)

If you feel interested in building a similar animal feed production line or livestock feed production business plan, and need detailed equipment list and price, don’t hesitate to contact us!

Animal feed pellets are a balanced combination of various kinds of nutrition, and crucial for the enhanced growth of cattle, goat, horse, etc. Livestock feed manufacturing machine which converts fodder raw mateirals into standard pellets fit for animal consumption, effectively making the feed easy to digest and palatable as well. And more and more farmers and business man spend times and moneys to start animal feed pellet production business due to the huge market. (Read more: Cattle Feed Plant Project Cost >>)

The raw materials for livestock feed pellets making include corn, wheat, soybeans, nutshells and other biodegradable materials such as grass, straw, and bagasse (sugarcane dregs). The feed pellets require an additional component of moisture, which is achieved by introducing steam or molasses to the mixture. Given that cattle, buffalos, cows and bulls all have diverse nutrition requirements, feed composition will contrast based on the type of livestock animal. The only constant is that the feed must be rich in energy, protein, and fiber. Setting up a animal feed processing plant can complete make high quality feed pellets for animal growth.

Video: The operation of the Feed Production Plant

Livestock feed production equipment for 2t/h production line – factory price feed pellet mill for livestock feed milling business: buy livestock feed production equipment from animal feed pellet mill manufacturer or supplier at factory price get FREE technical instruction of livestock feed pellet production and business plan to set up livestock feed pellet mill project in Philippines, Uzbekistan, Lithuania, Nigeria, Tanzania, etc., at low cost.

Facts of Livestock Feed Pellets Production

Varying the temperature and components can ensure a more refined pellet feed, both in terms of quality and nutritional value. Compared to traditional feed, pelletized feed products have more advantages, chief among them nutrient utilization and profitability. It not only reduces food wastage but is also easily stored and transported as well as widely preferred by the animals. (New Product: 800~1000kg/h Small Scale Cattle Feed Plant Cost)

Efficient Livestock Feed Production Process

Operating the livestock feed production equipment line can be relatively easy, but it is critical to adhere to the information manual as well as safety instructions furnished along with the machine. (Read more: Poultry Feed Manufacturing Plant Cost >>)

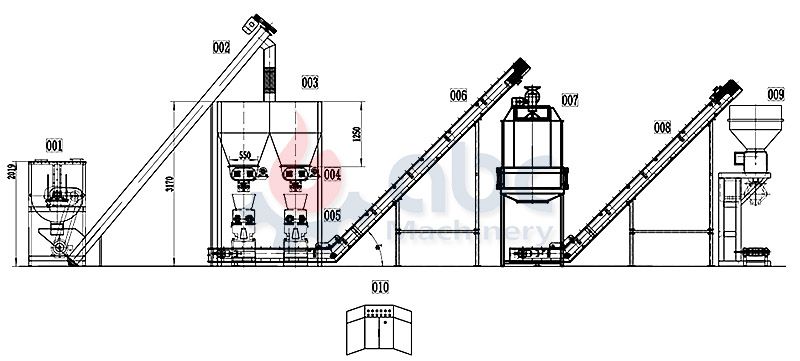

Fulll Equipment of 2TPH Livestock Animal Feed Pellet Mill Plant

1. Mixing Machine 2. Screw Feeder 3. Storage Silo 4. Feeding Device 5. Pellet Machine

6. Belt Conveyor 7. Pellets Cooler 8. Belt Conveyor 9. Bagging Equipment

Making livestock animal feed pellets require the raw fodder materials first be conditioned, then converted into powdered form and fused to create a mixture. A separate grinder and mixer can be used to accomplish this, with the subsequent mixture served into the feed pellet machine for the molding process to commence. The pellet machine exposes the powder to a variety of elements such as high temperature and pressure as well as steam, resulting in the compression of the powder into pellets. The processed mix is at that point passed through the holes of the die, being cut into the desired length in this extrusion process. An adjustable knife is ideal for this function, with the pellets subsequently put through a cooling process. Once parched, the pellets can be fed to the livestock animals.

Buy Animal Feed Processing Machine

Flat Die Feed Pellet Mill Vs Ring Die Feed Pellet Mill

There are two types of animal feed processing equipment on sale in the market: flat die type and ring die type. While the flat die mill machine is relatively economical, the ring die mill is more efficiency. Both are suitable for the setup of livestock feed pellet plant project for farming or business use. If you are not sure which one you should buy and can't find reliable animal feed equipment manufacturers, just contact us to get detailed technical information for your reference!

The livestock feed pellet machines differ in sizes and you should choose the right type based on your needs. Referring to complete animal feed production plant, some are integrated with grinders and mixers, while others utilize vapor. Steam not only extends die life, but also enhances production rate. (Related product: Flat Die Feed Mill Plant for 800-1100kg/h Production >>)

Large-scale production of feed pellet is done using ring die pellet machines while small-scale production utilizes flat die pellet machines. The ring die type machine is used to grind and mix, unlike the flat die mills which simply processes the dry powder into pellets. The ring die type machine is widely applied to production line of massive production of the feed and can produce about 1~15 tons of pellets each hour. (New Product: Ring Die Feed Processing Unit for 600~1000kg/h Production >>)

| Maize | Bran | Bean pulp | Mountain flour | Bone meal | Salt | Sodium bicarbonate | Growth peptide |

|---|---|---|---|---|---|---|---|

| 67.5% | 9.0% | 15.0% | 1.0% | 0.5% | 1.0% | 0.5% | 0.1% |

Build Your Future!

Build Your Future!