Start Livestock Poultry Feed Pellet Manufacturing Business

- Project: Livestock & Poultry Feed Mill Plant

- Production Output: 30,000 ton/year (5 ton/hour)

- Plant Location: Domestic

- Similar Project: 2~4TPH Animal Feed Pellet Production Line Set up in Uzbekistan

This is a complete poultry feed mill plant established in domestic. The production output is 30000 tonnes per year (5 ton per hour). This animal feed processing plant is designed for manufacturing feed for both livestock and poultry. (You may also like: 2TPH Poultry Feed Manufacturing Plant Cost in Uganda >>)

Commercial Poultry Feed Mill Design & Construction

Main Machinery for Complete Feed Pellet Mill Plant Setup

A large feed mill plant for poultry and livestock consists of several feed production machine. These machines perform their particular roles but have the mutual goal of producing small cylindrical pellets. (You may also like: Small poultry Feed Mill Machinery >>)

Commercial Feed Mill Machinery for Sale

The most basic equipment in a large scale poultry feed pellet manufacturing factory include crushing machine, feed mixing machine, pellet making machine, cooling machine, packing machine and etc.

- Crushing Machine: As the name indicates the function of this machine is to reduce the size of raw material. The most common raw material used for making poultry feed pellets is whole maize, maize bran, fish meal, soybean meal, cottonseed cake, brown rice, etc. Hammer mills are generally used as crushing machines.

- Feed Mixing Machine: A feed mixing machine is used to mix all the ingredients of poultry feed pellets. Mixing them is important to make sure that all pellets have the same amount or proportion of ingredients. While mixing ingredients, larger particles should be added before the smaller ones.

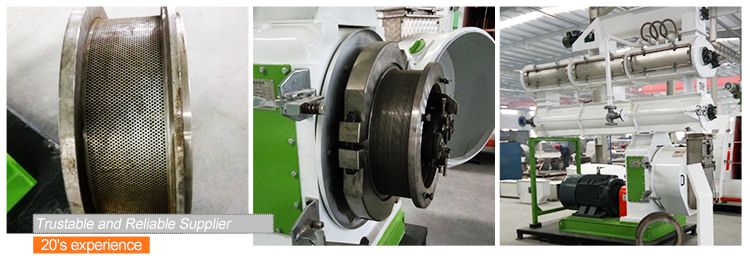

- Pellet Making Machine: Feed pellet mill machine put pressure on raw material and converts it into thin pellets of small size. In this machine water content of raw material decreases as temperature rises. Large scale poultry feed milling machine generally have a ring die. Rollers put pressure on the raw material due to which they start coming out of holes on the ring die in the form of solid cylinders. (Read more: Small Feed Pellet Machine Price >>)

- Cooling Machine: When pellets come out of holes of die they have an increased temperature which should be reduced before they are packed in bags. For this purpose, a cooling unit is used. In this unit cool air is used to reduce the temperature of pellets.

- Packing Machine: The packing machine packs pellets after weighing them in durable bags. Once pellets are packed, they are stored in the storage before they are sent to the market for sale.

Poultry Feed Mill Machinery Manufacturer

If you are planning to set up your own feed processing factory for livestock, poultry and fish, but don't konw how to start the animal feed business plan, don't hesitate to send us an inquiry and tell us your needs! Our engineers will help you make the best project plan with detailed equipment list and factory layout according to your specific situation, requirements and cost budget!

Complete Poultry Feed Mill Turnkey Project Supplier - ABC Machinery

Complete large scale poultry feed mill plant designed for commercial production – factory price feed processing machinery for livestock and poultry feed business: buy commercial poultry feed mill from feed mill machinery manufacturer or supplier at factory price get FREE technical instruction of poultry feed pellet production process and business plan to set up complete feed mill plant project in Philippines, Uzbekistan, Lithuania, Nigeria, Tanzania, etc., at low cost.

Advantages of Livestock & Poultry Feed Pellets

Compared with powder feed or mash feed, feed pellets produced by livestock & poultry feed mill plant has lots of advantages for poultry and farmers. (Read more: Buy Poultry Mash Feed Machine >>)

- Convenient for storage, packaging and transportation.

- High stability and not easily spoiled.

- Prevent the picky eaters, reduce feed waste.

- Increase feed density and feed intake.

Processing and Utilization of Roughage

Roughage is a type of feed in which the content of crude fiber in the feed dry matter is above 18%. Due to its high fiber content, large volume and difficulty in digestion, roughage feed has low nutritional value. Roughage feed includes hay, agricultural and sideline products (grains, shells, vines, vines, stalks, sorghum, etc.), leaves, and slag (bagasse, distilled grain). They have a wide variety of sources, large varieties, large production volumes, and low prices, and they are the main source of feed for grass-eating livestock. (Read more: Small Scale Cattle Feed Plant Cost >>)

- Wetting and Soaking: This process can not only softening the forage, but also can remove sediment, some tannins and abnormal odor, and can produce organic acids such as lactic acid, improve palatability and feed intake. Besides, it can also improve the nutritional value of roughage.

- Cutting and Crushing: Make it easy to stir, eat, and chew. The appropriate cutting length varies depending on the species and age of the animals. If too long, it is resultless. If too short, it is not good for chewing and rumination. Crushing can process hay and other roughage into various sizes of grass powder. The coarse fodder used by ruminants is generally not suitable for crushing. It is not only harmful to rumination, but also affects the digestibility of feed.

- Ammoniation: It helps improve the crude protein content of feed and can also improve the digestibility and palatability of organic matter in feed. For example, after the ammoniation of straw, the crude protein content can be increased by 5%~6%. And it soften the straw at the same time, so that to increase the palatability (the feed intake can be increased by 20%~25%).

- Fermentation: Degrade the crude fiber which is difficult to digest by animals, so that to improve the nutritional value of feed products.

- Pelletizing: During the pelletizing process, the function of mechanical force and steam treatment destroy the cell wall of the grain aleurone layer. As a result, the effective ingredients will be released from the aleurone layer and it is good for the absorption and utilization of livestock and poultry. Also, after processing into feed pellets, the crude fiber content is reduced, the carbohydrate is partially cracked and the starch is gelatinized, thus improving the energy utilization of the feed. In addition, the efficiency of phosphorus and the utilization rate of certain nitrogen base acids can also be improved by pelletization.

| Corn flour | Salt | Shell powder | Bran | Bone meal | Bean cake | Straw biological feed |

|---|---|---|---|---|---|---|

| 4% | 0.6% | 0.9% | 1% | 1.2% | 2% | 90% |

Build Your Future!

Build Your Future!