This is a mini copra oil refinery plant built in Cote d’Ivoire. It is based on semi-continuous refining process. The production capacity is 10 ton per day.

Photos of the Mini Copra Coconut Oil Refinery Project

The photos below were taken during the project constriction. (Related Project: 20TPD Copra Oil Pressing & Refinery Plant in Philippines)

Semi-continuous Copra Oil Refinery Plant

There are 3 types of refining process: batch type, semi-continuous type, and full continuous type. The semi-continuous oil refinery process is based on batch type but it is much more efficient and creates higher output with lower wastage. Semi-continuous oil refinery has a main process which is different from the batch type - that is deodorization. Besides, it is also cheaper than fully continuous oil refinery. The capacity of the semi-continuous oil refinery ranges from 10TPD - 50TPD and it is the best choice for medium-sized refinery.

You may be also interested in 20TPD Copra Oil Mill Plant in Philippines.

Section and Machines included in the Copra Oil Refinery Project

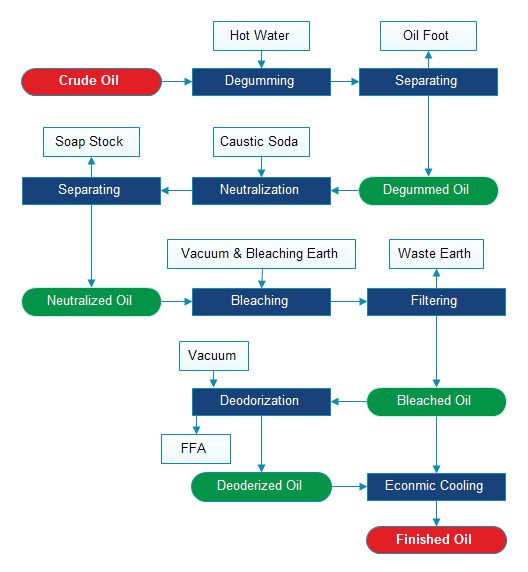

- Deacidification Section (Neutralisation): Sodium hydroxide (NaOH) is used which will react with the Free Fatty Acids (FFA) . This will discharge the soap stock which is the reaction product.

- Degumming Section: Warm water is used to blend with crude oil that removes the gum inside the oil. The oil is then dried for the bleaching process.

- Dewax Section: This helps to remove the wax from the oil in order to get a higher quality of oil.

- Decoloration Section (Bleaching): The bleaching earth is used to take out the impurities. The filter is then used to remove the bleaching earth.

- Deodorization Section: It is a semi-continuous process to remove the peroxide values in semi-continuous refinery plant. Deodorization tower is the main equipment. This is done to remove any serious smell from the oil.

- Press Filter: It filters clay and filters out clear oil. After deodorization, the oil will go through filter press and then final refined oil product is get.

- Heat-transfer Oil Stove: It provides heat energy to the devices that need it. Temperature can rise above 280A

- Vacuum Pump: It supplies with vacuum for de-odor, dehydrate, de-color. It can reach above 755mm Hg.

- Air Compressor: It blow dries bleached clay, blows empty the remaining oil in the press filter.

- Steam generator: It provides steam for deodorization and distillation.

Suitable Oil Plants for the Semi-continuous Refinery Process

Almost all kinds of crude oil can be processed in the semi-continuous oil refinery for manufacturing refined biodiesel oil and edible oil. (Related Project: 10TPD Oil Milling and 3TPD Refining Plant Built in Uganda)- Crude vegetable oil such as mustard oil, palm oil, coconut oil, and cottonseed oil, etc.

- Fruit oil such as avocado oil, olive oil, and grape seed oil etc.

- Crude animal oil such as fish oil, seal oil, etc.

Build Your Future!

Build Your Future!