Pressed soybean oil is one of the common edible oil processing techniques. It is welcomed by consumers because of its pure fragrance and rich nutritional value. The raw material for the production of pressed soybean oil is soybeans, which are low-oil content raw materials with an oil content of 16-24%. So how to produce pressed soybean oil from soybeans? How to design the soybean oil production process? Next, ABC Machinery will give a detailed introduction to each step in the soybean oil production process.

Build a Soybean Oil Production Plant

In addition, the market demand for processed soybean oil has always been great, attracting many investors who want to open soybean oil processing plants to make profits. In fact, setting up a small soybean oil plant does not require a lot of investment. As for what equipment is needed, it can be customized and produced according to the needs of investors.ABC Machinery designs, produces and sells various oil processing equipment. If you want to open a small soybean oil processing plant, you can click the button below to consult.

Detailed Introduction of Soybean Oil Production Process

- Cleanup process

Soybean raw materials used for oil pressing production may contain some impurities, such as dust, sand, small stones, metal impurities, husks, bad grains, etc. These impurities will not only affect the soybean oil production process, but also wear down the soybean oil pressing equipment and reduce its service life. So it is necessary to use cleaning equipment to remove these impurities.

The equipment used in the soybean cleaning process includes a magnetic separator machine, a vibrating screen machine and a stone remover machine. The magnetic separator uses the principle of magnet adsorption to remove metal impurities; the cleaning sieve uses differences in quality to remove impurities such as sand and hulls; the stone remover uses different densities to separate soybeans from stones. After the cleaning process is over, the soybeans will be transported into the crusher for crushing.

Two Soybean Cleaning Equipments

- Crushing process

The soybean grains are relatively large, which will affect the embryo rolling and pressing of the soybeans, so the soybeans must be processed into pieces with a crushing machine.This increases the surface area of the soybeans, so that the temperature and moisture of the soybeans are more evenly transferred during the softening and rolling, and the softening effect is improved.

- Softening process

Before the soybean embryo is rolled, it is necessary to carry out a softening treatment to adjust the moisture and temperature of the soybean. Soybeans are relatively hard and have low oil content. If the embryos are directly rolled without softening, a large amount of powder will be produced, which will affect the subsequent operations of the soybean oil production process. After being softened by the softening pot, the elastoplasticity of soybeans is changed, which is more conducive to rolling embryos.

- Rolling process

Embryo rolling is the process of using an embryo rolling machine to roll soybean grains into flakes, which makes it easier to steam and fry and squeeze. In the process of rolling the embryo, the cell tissue of soybean is destroyed by mechanical pressing, and soybean oil is more likely to flow out, which is beneficial to the pressing and extraction of soybean oil.

- Steaming and frying process

Steaming and frying is an important process in the soybean oil production process. It mainly changes the internal structure and state of soybeans through the effects of temperature and moisture, so as to accumulate oil and increase the rate of squeezed oil. At the same time, steaming and frying can also adjust the elasticity and plasticity of soybean cakes and change the quality of soybean cakes.

- Pressing process

Pressing is the process of extracting soybean oil from soybeans through the squeezing of an oil press machine. Due to the previous series of pretreatment processes, the temperature, moisture, and structure of soybeans have reached a good state suitable for pressing, so the pressing process is smoother and the pressing efficiency is also improved. The equipment used in pressing is an oil press machine, and ABC machinery can be equipped with one or several oil press machines according to investor needs and soybean processing capacity.

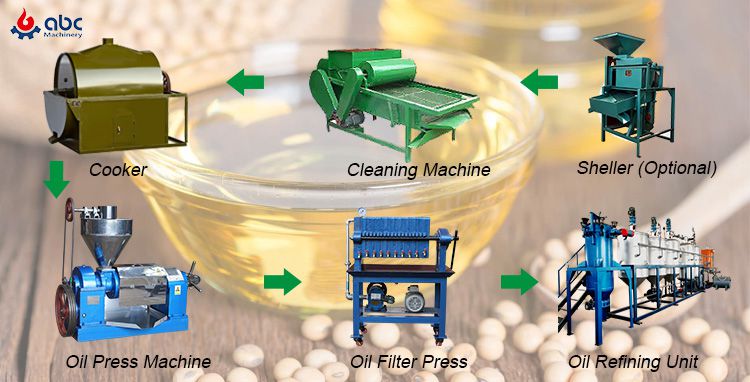

Equipment for Soybean Oil Production Process

The above full set of soybean oil production line is suitable for large and medium-sized soybean oil manufacturers with a soybean processing capacity of more than 10 tons per day. When the daily processing capacity of soybeans is less than 10 tons, or the investment budget of the manufacturer is low, a cost-effective single oil press machine can be selected as the soybean oil pressing equipment.

Processing Advantages of Different Soybean Oil Press Machine

Different types of soybean oil press machines have different internal structures and processing techniques.There are three types of oil press equipment provided by ABC Machinery:screw oil press machine, automatic temperature control oil press machine and multi-functional vacuum screw oil press machine.

Different Types of Soybean Oil Press Machine

(1) Screw oil press machine is suitable for pressing a variety of oils, with low investment, large processing capacity and high efficiency. More suitable for small edible oil processing plants.

(2) The automatic temperature control oil press machine replaces the traditional pressing and heating method, shortens the preheating time, reduces energy consumption and machine wear. The pressing temperature can be kept constant when the pressing is interrupted. More suitable for large, medium and small edible oil processing plants and private enterprises.

(3) The multi-functional vacuum screw oil press machine has increased the automatic temperature control function to ensure that the oil has a high oil yield and can improve the quality of the crude oil. A motor is installed under the oil press machine and protected by a protective cover, which not only greatly reduces the floor space, but also improves the safety performance of the machine. It is the product of choice for small and medium-sized soybean oil processing plants and individual enterprises.

You can choose a full set of soybean oil pressing equipment or a single oil press machine according to your needs. ABC Machinery can also customize soybean oil processing plans and provide corresponding soybean oil equipment according to your needs, don't hesitate to contact us!

Build Your Future!

Build Your Future!