How Much is Edible Oil Bottle Filling Machine?

Choose an oil bottle filling machine to boost production efficiency and cut costs! Compared to manual filling, an oil bottle filling machine automates the filling process, significantly reducing production time, enhancing efficiency, and saving on labor costs. Moreover, automatic control ensures precise and reliable filling every time, eliminating the human factor's impact on product quality.

Start with hygiene and safety during filling at the plant! The automation control of the oil bottle filling machine ensures cleanliness and hygiene throughout the filling production process, providing a solid guarantee for the safety of your products. This not only ensures the safety and quality of what you produce but also helps maintain continuous trust in your business from your customers.

Accurate labeling to highlight quality and competitiveness! The oil bottle filling machine not only automates the filling process but also handles labeling automatically. It can precisely and neatly apply product labels, enhancing your brand image and market competitiveness, while catering to the diverse needs of different customers.

Boosting Production Efficiency: How to Choose Right Oil Bottle Filling Machine?

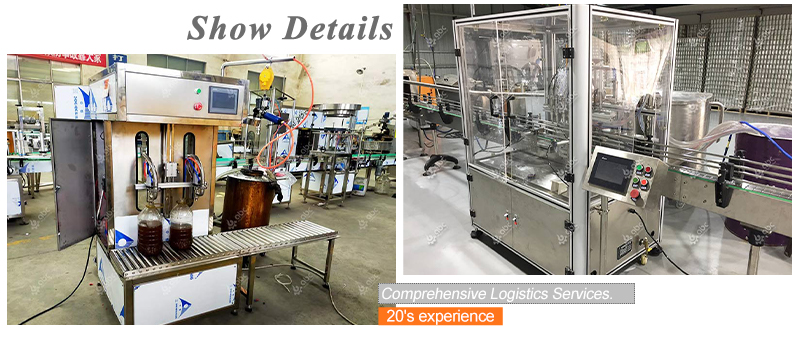

Semi-automatic(Left) and Automatic(Right) Oil Bottle Filling Machine at Low Price

Classification of Filling Machines Based on Measurement Methods

- Flowmeter-based Filling Machine

-

Advantages:

Accurate flowmeter measurement, suitable for precise filling production of edible oil.

Applicable to edible oils with different viscosities and concentrations, able to adapt to characteristics of different products.

Relatively fast filling speed, suitable for large-scale production line.

Relatively simple operation, no need for frequent calibration and adjustments.

Limitations:

Calibration and adjustments of the flowmeter may be required for edible oils with different viscosities.

Flowmeter-based filling machine may be affected by blockages in edible oils containing particles or solid particles.

Due to the mechanical nature of flowmeters, maintenance and replacement may be necessary after prolonged use.

- Weighing-based Filling Machine

-

Advantages:

Weighing-based filling machines can accommodate edible oils with different densities and viscosities without frequent adjustments.

They can handle edible oils containing particles effectively.

High filling accuracy, suitable for precision filling requirements.

Not affected by issues like flowmeter blockages.

Limitations:

Relatively slower filling speed compared to flowmeter-based filling machines, suitable for medium to small batch production.

Requires presetting and adjustments for different weight ranges of edible oil.

Equipment maintenance is relatively complex, involving regular inspection and calibration of sensors and weighing devices.

Sale Oil Bottle Filling Machine - Rotary Type(Left) & Linear Type(Right)

Classification of Filling Machines Based on Working Principles

- Rotary Filling Machine

-

Working Principle: Rotary filling machines typically have a circular turntable where containers are placed. The turntable rotates around a central axis, passing through different workstations, each performing an operation such as filling, sealing, capping, etc.

Automation Level: Typically has a higher level of automation.

Advantages:

Uses electronic weight measurement for high filling accuracy. For example, for 5-liter containers, overall filling accuracy can reach 0.05%.

High production capacity, small footprint, and low noise.

Suitable for high-speed production lines.

Limitations:

Cleaning and maintenance can be challenging.

Limited adaptability to container sizes.

There's a minimum requirement for the number of filling heads; generally, it's suitable for machines with a dozen or more filling heads.

- Linear Filling Machine

-

Working Principle: Linear filling machines move containers along a linear conveyor belt (usually in a straight line) and perform various operations at different workstations along the line, such as filling, sealing, capping, labeling, etc.

Automation Level: Typically ranges from semi-automatic to fully automatic, depending on the specific configuration.

Advantages:

Suitable for high-precision filling production, achieving accurate quantification.

Adaptable to various container types and sizes with simple workstation adjustments.

Easy integration with other automation processes like capping and labeling.

Limitations:

Relatively lower production capacity.

Larger machines may require more space.

For friends planning to invest in a sunflower oil factory, an automatic oil bottle filling machine can effectively save labor costs, time, and increase efficiency with precision. Without specialized filling equipment and relying on manual filling, it could lead to low work efficiency, wastage of labor costs, and potentially significant overuse of raw materials.(Read More: Oil Bottle Filling Line in Jamaica>> )

What Factors Affect the Accuracy of Oil Bottle Filling Machines?

The accuracy of an oil bottle filling machine can be influenced by various factors, including business considerations, production efficiency, and cost-effectiveness. It's important for everyone involved in the production process to have a certain level of understanding about these factors before the filling process. Here are common factors that affect filling accuracy, which in turn can impact the business's profit and production cost.(Related Article: Complete Coconut Oil Filling Line in Sri Lanka>>)

A Complete Edible Oil Bottle Filling System Setup

- Filling Equipment Quality: The manufacturing quality and materials of the machine determine its stability and accuracy. High-quality equipment typically comes with better control systems and stability, leading to higher precision.

- Filling Oil Characteristics: The properties of edible oil may vary depending on the variety and temperature, such as viscosity, density, and flowability. These characteristics can impact the filling accuracy as different oils may exhibit different flow behaviors under the same setup and process. Understanding these variations is crucial to optimizing unit cost and ensuring efficient production.

- Filling Speed: During the filling process on the prodction line, if the speed is too fast, the dynamic force of the liquid may lead to overflow or fluctuation, thereby affecting the accuracy of filling.

- Filling Volume Setting: As operators, it's crucial to ensure the correct input of the required quantity when setting the filling volume on the machine or unit responsible for the filling process. Errors may occur during the volume setting and accumulate over multiple fillings.

- Equipment Cleanliness and Maintenance: If the filling machinery is affected by oil, dust, or other contaminants, it may lead to blockages in valves, sensors, or pipelines, thus affecting precision.

- Surrounding Environment: Factors like ambient temperature and humidity may also influence filling accuracy. For instance, excessively high temperatures could lead to dilution of the oil, affecting the accuracy of filling volume. Therefore, it's important to consider these environmental factors in the production setup and design to maintain consistent production quality.

- Operator Skill Level: If operators are not familiar with machinery operation or incorrectly adjust settings, it can result in reduced filling accuracy.

- Equipment Calibration : Operators need to regularly calibrate the edible oil bottle filling machine. If the equipment goes without calibration for an extended period, it may lead to a gradual deviation from the expected filling volume.

- Filling Container Shape: Different container shapes and sizes can impact the stability and accuracy of the filling process. It is recommended to use standard containers that are suitable for the equipment to ensure precision. If there's a temporary switch to a different bottle type, timely communication with the oil bottle filling machine manufacturer's technical personnel is advised.

If accuracy becomes unstable, it not only affects the stability of the edible oil filling production line but also the quality of the final product. Therefore, it is hoped that every investor will pay attention to the above-mentioned factors when using the filling production line equipment, and perform maintenance and upkeep to ensure the long-term and stable operation of the production line.

ABC Machinery is committed to providing customers with products of better quality and higher cost-effectiveness. We offer a range of services, including customization, installation, training, and maintenance, to meet various customer requirements. If you have any other needs or further questions, please feel free to contact us. We are happy to provide you with more information and discuss your project requirements.

Build Your Future!

Build Your Future!