Sawdust is a very common pellet raw material, especially in sawmills, which is produced during the process of wood sawing, sanding, milling, planing, and routing. As a fuel pellet, sawdust is widely popular worldwide. A large amount of sawdust is produced every year, especially in Brazil, Russia, Canada and China. These huge amounts of sawdust facilitate the large -scale production of sawdust pellets.

The thermal value of the sawdust is determined by the lignin. The higher the lignin, the higher the thermal value, and the lignin is also helpful for pellet processing. Making sawdust into wood pellets, both for commercial purpose or household use, has been hot topic in recent years.

Sawdust Pellet Making for Business

According to pmarketresearch, the sale of global wood sawdust pellet will reach 30 billion tons and $4550 million in revenue by 2022. And, the increasing of costs, crisis and depletion of conventional energy sources accelerate the development of wood pellet production business. As present, the wood pellets in European countries are about 300 €/T and it will rise to 400 €/T by the end of September/beginning of October. Therefore, starting sawdust pellets production business is an an absolutely rewarding investment. Before setting up or buying sawdust pellet making machine, it is highly recommended to comprehensive understanding about how to make wood pellets from sawdust.

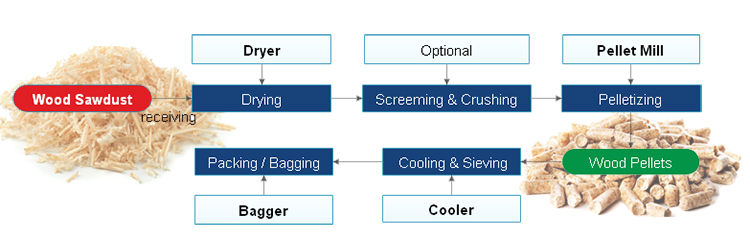

Wood Sawdust Pellet Production Process - Designed for Commerical Wood Pellet Plant

Detailed Sawdust Pellet Production Process

- Sawdust Preparation

The first process to make wood pellets from sawdust is to prepare the raw materials. The collected sawdust cannot be processed directly. The water content of the sawdust should be tested first, and the sawdust with high water should be treated separately. The best water content for the production of pellets should be 10% to 15%, if moisture content is higher, it should be dried first.

- Sawdust Drying

The main purpose of drying of sawdust pellet making is to adjust the moisture content, so that it is stable and uniform, suitable for wood pelletizing process. Appropriate moisture, on the one hand, can transfer the pressure of pressure roller, on the other hand, can play the role of lubricant to assist particles fill each other, thus promoting sawdust pellet forming. However, when moisture content is too high, the moisture tends to form a barrier layer between the particles, making it impossible for the layers to be tightly bonded, and the extruded pellets tend to swell and spread out, making it impossible to shape them. Therefore, biomass pellet plant requires the moisture of raw materials to be between 10-15%. The moisture required in the market for wood pellets is generally 8-10%. This moisture is close to the humidity of the air, which makes it easier to store and transport. So, sawdust must be dried before pellet production if they do not meet the moisture content. (Related Equipment: Drum Dryer >>)

Drying System in Sawdust Pellet Plant

- Sawdust Screening and Crushing - Optional

The raw materials need to be screened because the raw materials may mix other hard materials such as stone, metal, plastic, etc. These hard foreign bodies will cause damage to the equipment. During the screening process, stones are cleaned up by Stone Trap, and metals will be cleaned up by the magnetic selector. Because there may be large pieces of wood chips or wooden blocks in the sawdust, crushing needs to be processed so that the size of the raw materials become consistent and suitable for the processing, so that it can make it smoothly pass through the die holes of sawdust pellet pellet mill.

- Sawdust Pelleting

During the operation of the sawdust pelletizer machine, heat will be generated, which will heat the sawdust to 120 to 130 ℃, the lignin in the sawdust will play a role at high temperature, the sawdust will be bonded together, then pressed and shaped under the action of the die hole, and then cut into a specified length by the cutter. If the lignin content is insufficient, and the raw materials cannot be bonded together, an adhesive can be added to shape the pellets and improve the strength and durability of the pellets. (You may also like: Sawdust Briquette Machine Price >>)

Sawdust Pellet Mill Machines for Sales

- Sawdust Pellets Cooling

The newly formed pellets are very hot, and these pellets need to be cooled to hard and dry state with the help of the cooler. The water content of the pellet water after cooling can be as low as 6%. After that, the pellets will absorb some water in the contact with the air, and the water content will stabilize at 8% to 10%.

- Sawdust Pellets Packaging

The made pellets need to be packaged to facilitate transportation and storage. It should be noted that the pellets need to be screened again before packing to sieve off the fine powder and recycle fine powder. If the pellets are transported in home, they should be packaged in 12, 15 or 20 kg. If the pellets need to be transported abroad, they should be packed in 1 ton or directly transported, and wrapped in plastic to prevent moisture. Small wood pellet bagging machine is a more recommended pellet packaging method, so that the pellets can be worn less during transportation.

Above content will have a detailed introduction on sawdust pellet production process, but it is mainly for medium and large scale wood sawdust pellet processing, if you are more interested in small scale sawdust pellet making, just see more at small scale wood pellet production machines.

Engineering Project: How to Make Wood Pellets from Sawdust?

How to Calculate the Cost for Each Sawdust Pellet Production Process?

When the sawdust pellet plant is sucessfuly completed and commissioned, the main cost for sawdust pellet production will be raw materials, the running of machines, the wear and tear of ring dies, the labors, etc. Since different capacity and different regions, the cost will vary much, therefore, if you want to get exact cost of a sawdust pellet plant, just contact us and offer details, our engineers will help to calculate it according to your specific needs. (Read more: Wood Pellet Business Plan >>)

Most importantly, we can supply you a lot of wood pellet plant project for reference based on your buget. Believe me, you can find all about sawdust pellet making at ABC Machinery, just send you request in details.

Build Your Future!

Build Your Future!