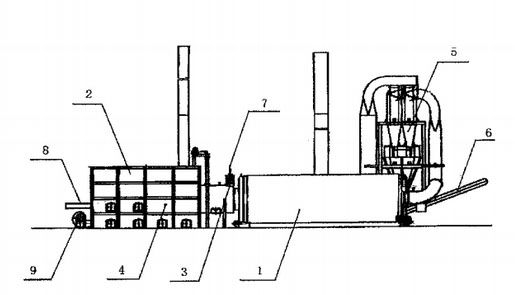

This rotary drum type dryer machine is designed specifically for drying system of biomass wood pellet production. It is mainly composed of combustion fan, calcining furnace, screw conveyor, dryer, dust-collecting fan, temperature sensor. Both the main dryer and calcining furnace are equipped with temperature sensor. The screw conveyor is equipped with speed setter. The calciner is designed with combustion air duct.

This wood dryer machine offers an effective solution to the biomass drying process, solved the drawbacks of traditional drum dryer such as drying uneven and insufficient. It is widely be used to dry various different biomass powdery materials including sawdust and bamboo powder. This biomass drying machine is featured of simple operation, high fuel efficiency, uniform drying and low dust emission concentration.

| Model | Φ0.8×10m | φ1.2×10m | φ1.5×11m | φ1.8×11m | φ1.8×14m | Φ2.0×15m |

|---|---|---|---|---|---|---|

| Air fan power | 15kw | 22kw | 30kw | 45kw | 45kw | 45kw |

| Inner diameter | 800mm | 1200mm | 1500mm | 1800mm | 1800mm | 2000mm |

| Length | 10m | 10m | 11m | 11m | 14m | 15m |

| Temperature of inlet air | 180-350℃ | 180-350℃ | 180-350℃ | 180-350℃ | 180-350℃ | 180-350℃ |

| Temperature of outlet air | 90-100℃ | 90-100℃ | 90-100℃ | 90-100℃ | 90-100℃ | 90-100℃ |

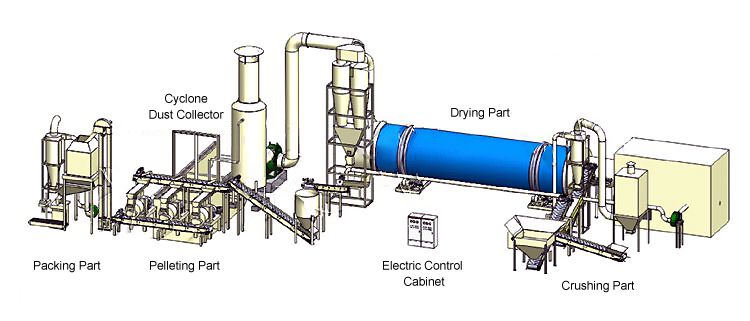

Drying System of Biomass Pelletizing Line

Drying machine includes drum dryer, the three return dryer, intermittent dryer, direct heat dryers and other types. Drum dryer is the most commonand widely used one in industrial production such as biomass pelletizing line. Drum dryer is also known as cylinder dryer or rotary dryer.

Main Structure of Biomass Drum Dryer

- Main Dryer Machine

- Calciner

- Screw Conveyor

- Temperature Sensor

- Dust-collecting Fan

- Belt Conveyor

- Main Drive Gear

- Combustion Air Duct

- Combustion Air Blower

Advantages of Drum dryer

High thermal efficiency, low consumption;

Match with a variety of combustion furnace.

Simple Structure, easy operation.

Low cost and easy maintenance.

Greater capacity.

Less malfunctions, easy maintenance and convenient to repair.

This wood dryer machine offers an effective solution to the biomass drying process, solved the drawbacks of traditional drum dryer such as drying uneven and insufficient.After drying, the moisture content of biomass materials is lower than 7%, black smokeless thanRingelmannGrade I,dustconcentration less than 80 milligrams per cubic meter. In a word, this drum dryer has obvious advantages compared with traditional drum dryer.

| Drying Effects | Biomass Drum Dryer | Traditional Drum Dryer |

|---|---|---|

| Moisture Content(%) | 7~8 | 10~13 |

| Black Smoke (Ringelmann Grade) | 1 | >1 |

| Smoke Density (mg/m3) | 75~80 | 120~150 |

| Fuel Efficiency (%) | ≈100 | 90~95 |

Build Your Future!

Build Your Future!