Market Analysis of Wood Pellets

Affected by the war and energy crisis, biomass pellets are now in great demand around the world, especially in Europe, the retail price of wood pellets is around €500 without taxes (15kg bags), in bulk (big bag) €350. And the price is going to rise, when the winter is coming. And the biomass pellets market is expected to total $10,270.9 Mn in 2022. Countries in North America and Europe are the main consumers of biomass pellets. Now, the comsumption of biomass pellets are far more than the productiom of biomass pellets. (Project: 1TPH Wood Pellet Production Line Setup in UK >>)

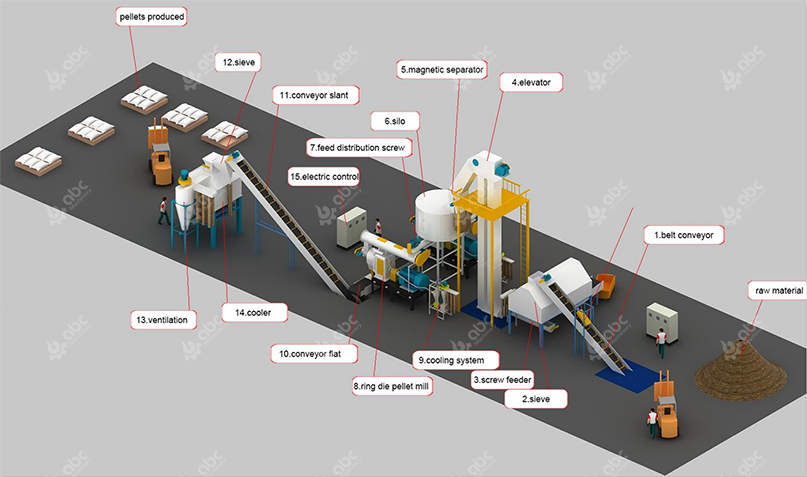

Wood Pelletizing Processes and Main Biomass Pellet Machinery

The complete wood pellet production process is roughly divided into: chipping, crushing, drying, pelletizing, cooling and packaging. Therefore, a variety of different equipment is required to complete these steps. Common biomass pellets production machines include chippers, hammer mills, dryers, pellet mills, cooling and packaging machines. (Read more: Wood Pellet Plant Design >>)

Complete Wood Pellet Plant Layout Design

- Chipping: this process is mainly to chip wood logs or wood blocks so as to reduce the difficulty of crushing and crushing power. Generally, this proces can make wood from the diameter of 50cm into 5mm. Wood chipper should be decided by the capacity of the whole wood pellet plant and the size of the diameter of the wood.

- Crushing: it is mainly to crush wood chips into smallest pieces further so as to facilitate wood pelletizing process. Biomass pellet plant designed by ABC Machinery adopts a combination of positive and negative pressure discharge and dust removal method, effectively reducing the wear and tear of the fan and dust.

- Drying: it will help to reduce moisture content of raw materials (20%~60%) to required standard, generally 10%~15% for pelletizing. The drying machine selection is also the key factors to lower the cost for biomass pelletizing business. In most cases, the moisture of raw materials and the moisture of discharge will determinte the drum dryer and the hot air furnace.

- Pelletizing: it is the core process of the whole wood pellets production line. Wood pellet mill machine can process wood chips into pellets with diameters of 6mm,8mm,10mm,12mm. And, the hot sale wood pellet mills in the market are flat die pellet mill for small scale wood pellets production and ring die pellet mill for large scale wood pellet production. (Related machine: Vertical Ring Die Pellet Mill >>)

- Cooling: In the latter stage of pellet production, the cooling machine is applied. The use of this machine enables the temperature of the pellets to drop from 80-90°C to room temperature. It can also reduce the moisture content from 17-18% to 12-13%.

- Packaging: The finished pellets need to be packaged before they are sold to customers, generally using bags and tons of bags. This section is sealed according to the customer's requirements, the automatic packaging machine used, the packaging volume is large, the labor occupies less, will greatly reduce the packaging costs.

Cost to Setup a Wood Pellet Making Plant

Since 1992, ABC Machinery has been providing biomass pelletizing solutions for domestic and overseas customers. With these years’ development, we have owned advanced fabricating machinery for premium qualitya and efficient wood pellet machines. And the same time, we also keep updatinig the wood pelletizing technology so as to help our customers to keep invincible position in fierce market competition. Most importantly, we are also dedicated to lowering investment cost to setup a commercial wood pellet plant by optimizing equipment selection and plant design. (You may also like: Small Biomass Pellet Project Cost >>)

Complete Wood Pellet Plant Cost

To some extent, wood pellet manufacturing business is cost intensive industry, especially for industrial/commercial wood pellet plant. In general, cost for wood pellet plant main include two parts: the setting up cost and the running cost. The setting up cost of a complete wood pellet plant is decided by equipment price. Therefore, a reliable wood pellet mill manufacturer would be critical. It is highly recommended to purchase equipment from branded suppliers.

Here we briefly introduce the main cost to produce 1 ton wood pellets for your reference.

- Raw Material Cost

The current price of raw materials (sawdust, wood chips and wood shavings) for wood pellet production is about 60~80 usd/t. But raw materials need to remove the moisture content, usually 20~60%, to 8%. Let’s take the moisture content as 40%. Therefore, the cost for raw materials for 1 ton is about 88~117usd/t.

- Power Consumption Cost

For a complete wood pellet plant, the power consumption cost is mainly from wood pellets machines, especially the pelletizing machine and drying machine. The electricity price is different a lot from regions to regions. Here, we just take the power price in China as an example. It is about 15~20usd/t.

- Vulnerable Part maintenance Cost and Equipment Depreciation Cost

For pellet mill machine, there are some quick-wear parts that should be replaced regularly, including dies, rollers, lubricants, seals, etc. And, the equipment depreciation and maintenance cost are also needed. Both are about 5~7usd/t.

- Labor Cost

There would need 3~4 workers for the whole pellet production line. Generally, in China, the cost for labor for one ton is about 2usd.

Above mentioned cost is not absolute since there are great difference when the regions are different. Therefore, if you are going to make an accurate cost analysis report about your wood pellet manufacturing business, just contact any time and our professional engineers will offer full supprts and helps.

Significance of Wood Pelletizing Business

Biomass pellets are a clean energy source with little pollution to the environment. It can replace coal, oil and gas, and is a highly efficient and energy-saving environmental protection product. Biomass pellets are easy to realize mass production and use. The main raw materials of biomass pellets are: agriculture, forestry and other wastes.

- Agricultural raw materials: straw, peanut shells, bagasse, alfalfa, coconut shell, palm shell, corn stalk, cotton stalk, etc.,

- Wood raw materials: logs, chips, shavings, sawdust, bark, etc

- Other wastes: manure, etc

Biomass energy is the fourth largest resource in the world and occupy an important position among renewable energy sources. The energy problem has been a decisive factor affecting the socio-economic development of various countries today. So, investing in biomass pellet plant has very good economic and social benefits.

Feasibility of Wood Pelletizing Business

It is no doubt there are great market demand for the biomass wood pellets. And, the biomass raw materials that has been utilized are just a very very small part on the earth. Therefore, there are great potentials for wood pelletizing business, it is profitable and environment-friendly.

Benefits of Wood Pellets

Pellet fuel is made by extruding wood chips, straw and other raw materials under normal temperature conditions using pressing rollers and ring die. The density of raw materials is generally about 130 kg/m3, and the density of pellets after pelletizing is more than 1100 kg/m3, which is convenient for transportation and storage, and the fuel performance is greatly improved.

Wood Pellets Uses:

Civil heating and domestic energy: high combustion utilization and easy storage.

Biomass industrial boilers: as the main fuel for industrial boilers, replacing coal and solving environmental pollution.

Power generation: It can be used as fuel for thermal power generation.

Performance index of biomass pellet fuel

| Intem | Index |

|---|---|

| Calorific Value | >4000Kcal/kg |

| Ash Content | <=1.1% |

| Moisture Content | <=8% |

| Combustion Ratio | >=95% |

| Thermal Efficiency | >=81% |

| Ringlman Emittance | <1 |

| Discharged Dust Consistence | <=80mg/m3 |

Build Your Future!

Build Your Future!