Hard wood pellets are a renewable source of fuel made from 100% natural hard wood. Hardwood is wood that is gotten from angiosperm trees. There are different species of these trees, such as oak, pine, cedar, poplar, beech, cottonwood, hard maple, elm, birch, hickory, pecan, and yew.

Turnkey Project Solutions for Hard Wood Pellets

Hard wood pellets that made through professional biomass pelletizing process is getting more and more popularities around the world, especially in today when energy crisis becomes apparent. Investing to hard pellet production now can be a perfect opportunity to start with since the price of biomass wood pellets. (Related post: Softwood VS Hardwood Pellets >>)

In Europe, the retail pellet price is around €500 without taxes (15kg bags). In bulk (big bag) €350. And the cost of electricity is more than doubles to €0.65KWH the last year.

Business Plan for Hardwood Pellet Production

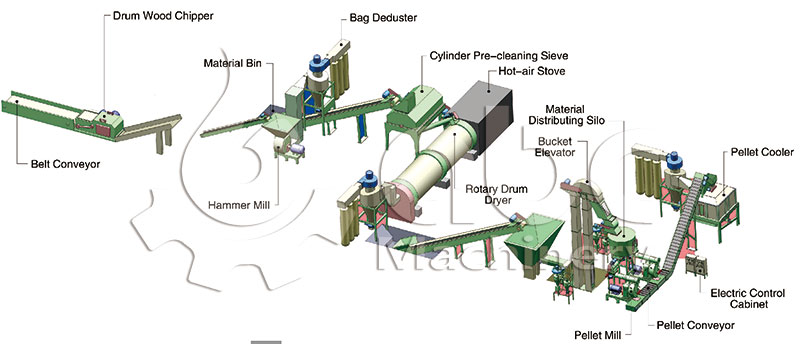

Factory Layout and Equipment List of Hard Wood Pellet Plant Project

In view of the current international situation and biomass energy developments trend, it is definitely profitable to start hard wood pellets making business, especially in North America and Europe. The increasing use of biomass pellets in the power industry is positively influencing the growth of the biomass pellets market. Moreover, the rising demand for renewable energy is another important factor which is supporting the adoption of these pellets in the power industry. If you want to establish your own hardwood pellet factory, then there are certain requirements that you must take note of. We will take a look at some of them in this section.

Cost of Wood Pellet Processing Equipment:

The equipment for a hardwood pellet production plant depends on the type of raw material. Hardwoods generally require wood pellet machines with a low compression ratio. You must also take note of the raw material sizes. For example, logs cannot be processed directly with biomass wood pellet mill; you will have to use a hammer mill. Another thing to consider is the amount of raw material the factory would be processing on a daily basis. If the factory is to have a large output, then it would require bigger and more advanced equipment.

Factory Price Ring Die Pellet Machine for Hard Wood

Surely, a well-known and reliable wood pellet mill manufacturer or supplier will help a lot when buying the wood pellet machine. In most cases, they can help on equipment selection, cost estimation, profits calculation, factory design and equipment installation, etc. Below is some samples of the wood pellet plant designed for our customers.

Cost of Raw Materials

After determining the right material for the factory, the next thing to do is to find out stable supply for the raw material so as to reduce the hard wood pellet production cost. This usually depends on the type of feedstock, because some wood are more expensive than others. The two most common types of feedstock are wood and virgin fiber. A ton of wood costs between $55 and $65, while that of virgin fiber costs around $70-$80. Remember to include the cost of processing since the raw material you choose will determine this. Different feedstocks have different moisture content, which will usually range from 40–60%. When compared to wood, virgin fiber has a higher moisture content. High moisture content means more processing costs because it would require plenty of energy and time to dry the raw material to the optimum moisture content.

Cost of Energy and Maintenance and Repairs

The cost of processing one ton of feedstock is around $10. However, this could be different from one location to another. Factories in countries with higher energy costs will spend more than those with lower energy costs. While planning your budget, you should include the potential cost of maintaining and repairing the factory equipment. On average, processing one ton of feedstock will cost you around $5 in maintenance and repairs.

Labor Cost

The cost of labor will depend on the planned production capacity and the automation level of the pellet factory.

Cost of Transportation and Storage

This is another very important expense that must be factored into your budget. It depends on the location of your factory, so you should consider the cost of the rail or other means of transportation for shipping the pellets. You should also consider how much it will cost to store the pellets in warehouses before they are loaded and shipped.

Cost of Constructing Factory:

The total cost of constructing your hardwood pellet factory would depend on the location. Constructing the factory in a European country would cost more than in Canada or the United States because the cost of energy is higher in Europe.

Although this list will give you an idea of what you will need to get started, in order to be profitable, you should still consult an expert. In the hardwood pellet industry, you can talk to your biomass pellet machine suppliers. They will give you relevant information on the best choice of raw material, recommended pellet output, estimated budget, and so on.

Since 2004, ABC Machinery has become a global specialist in providing turnkey biomass pellet plant. Biomass pellet plant projects successfully set up by ABC Machinery cover Asia, America, Europ, Africa and Oceania. In countries, like Vietnam, Pakistan, Korean, Japan, Thailand, Indonesia, Malaysia, Australia, Portugal, Italy, Bulgaria, United Kingdom, Romania, Russia, Morocco, Ghana, Egypt, Chile, Peru, etc.

We boast strong capacity to undertake turnkey project for hard wood pellet milling plant by offering great after-sales services which include staff training, repairs, and maintenance. You’re very welcomed to contact and talk about issues you encounted in the process during preparing or starting wood pellet plant!

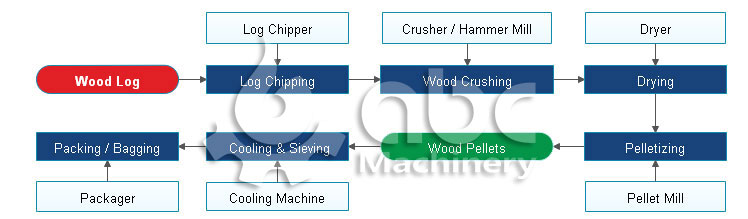

Hardwood Pellets Production Process

The process of producing hardwood pellets is quite easy. In order to manufacture high-quality hardwood pellets, you should find a reputable supplier to provide you with the required wood pelletizing machinery. Once you have done this, then follow these steps:

Detailed Process to Make Hard Wood Pellets

- Prepare Raw Materials

Many pellet factories accept different forms of raw materials. These could arrive in the form of full trees, wood chips, sawdust, or even lumber mill scrap. Therefore, they could be freshly cut, partially dried, or kiln dried. So, it is important to prepare them properly so that they can have the same moisture content, burn characteristics, and ash content. This will allow them to burn consistently. The large pieces of hardwood are processed by putting them through a chipping machine (a chipper). On the other hand, hammer mills are used to break down wood chips and sawdust into consistently small sizes so that drying and pressing can be fast.

- Drying

The moisture content of the raw materials must be maintained at between 10 and 15%. Freshly cut wood or materials exposed to high humidity or open weather will have high moisture content. After the initial preparation, these materials would be placed into large dryer drums where sawdust burners, natural gas, or propane would be used to heat the drums and remove moisture.

- Pelletizing

Once they are properly dried, the raw material is fed into the pellet mill hopper. They are pressed at high pressure, which heats them up and releases lignin in the wood to bind them together. The mill used determines the diameter, length, density, and durability of the pellet. (Newly developed machine: Vertical Ring Die Pellet Mill for Sales >>)

- Cooling

As the pellets are made, they go into the collection bin. They would be soft and fall between 200 and 250 degrees. Before they can be packaged, they will be cooled in a pellet cooler or cooling tower. This will reduce the temperature of the pellets and make them hard.

- Bagging

Hardwood pellets are usually packed in bags. The bagging process can be done manually by hand or with a sealing machine. It can also be carried out automatically with a pellet packaging machine that bags the pellets.

The hard wood pellet production processes can be add or reduce some to meet the requirements for your business plan and biomass pellet project cost. Detailed specific wood pellet production process is a combination of various factors and designs.

Market Demand for Hardwood Pellets

Why people like to buy hard wood pellets? It is no doubt that its market popularity is closely related with its excellent characteristics:

Profitable Investment on Hard Wood Pellet Processing Project

- hardwoods are dense, which means that the pellets have high energy content and are therefore great for heating.

- hardwood pellets burn slowly but are usually hotter than other pellet types.

- Hardwoods have lower moisture content, which makes the pellets burn for longer.

The increasing demand for cheaper and more environmentally-friendly sources of energy has led to the development of alternative sources of energy. One of these alternative sources is wood pellets. When compared to popular sources of energy such as oil, coal, or natural gas, wood pellets are less expensive and are not harmful to the environment. For these reasons, many investors have started to enter the hardwood pellet industry.

Differences Between Hardwood Pellets and Softwood Pellets

Many people believe that hardwood pellets are far better than softwood pellets. However, this is not true, as the two raw materials have their advantages.

- Price: Hardwood pellets are often more expensive than softwood pellets. The major reason for this is that hardwood raw materials are sold at a higher price than softwoods.

- Heat Output: Softwood pellets produce 10–20% British Thermal Unit (BTU) heat, slightly more than hardwood pellets. This is due to the presence of more sap in softwood, which helps them burn more quickly.

- Ash Content: Based on several studies that have been carried out, some hardwood pellets may contain up to three times the ash content of softwood pellets. The ash content is also affected by the cleanliness of the raw material and the quality of the pellet mill.

The pressure and heat during the pelletizing process changes the density and structure of the raw materials. This shows that the quality of the pellets produced is determined by the quality of the pellet machine and not the raw materials used.

Build Your Future!

Build Your Future!