Why Edible Oil Requires Oil Refining?

Oil is the necessity for human being living. Edible oil is one of the main nutrients in food. Oil is also the main origin material for food industry and light industry. Some oil products play an important role in some industries, such as national defend, metallurgy, textile, medicine and so on. Normal vegetable or animal oils obtained through pressing, leaching, water solvent or smelting and haven’t been processed through oil refining process are collectively called crude oils. Crude oil contains many kinds of foreign matters, such as solid residue, sand, oil cake residue; solloid-soluble impurities, such as phospholipid, protein; oil-soluble impurities, such as free fattyacid, pigment, aflatoxin, gossypol; and moisture. All the above impurities can easily cause rancidity, devalue and degrade the quality of vegetable and animal oils. Therefore, it’s necessary to remove off these foreign matters according to their different properties and using requirements so as to satisfy the requirements of the edible oil industry. That is why the crude vegetable oil or animal oil need the oil refining process.

In order to meet the needs of oil refining of various oil plants at home and abroad, ABC Machinery specially develops cost effective oil refinery plant equipment with the capacity ranges from 1TPD to 400TPD. Our edible oil refining machinery can production high quality edible oil compliant with international standards. The methods for oil refining has three types, batch, semi-continuous and continuous. The oil refining equipment between 1~20TPD usually adopts batch oil refining process, the capacity above 20TPD adopts semi-continuous or continuous oil refining process. All the process and method are designed based on the actual requirements to maximize input-output ratio. (You may also want know the Small Edible Oil Refining Cost >>)

Oil Refining Production Process and Equipment

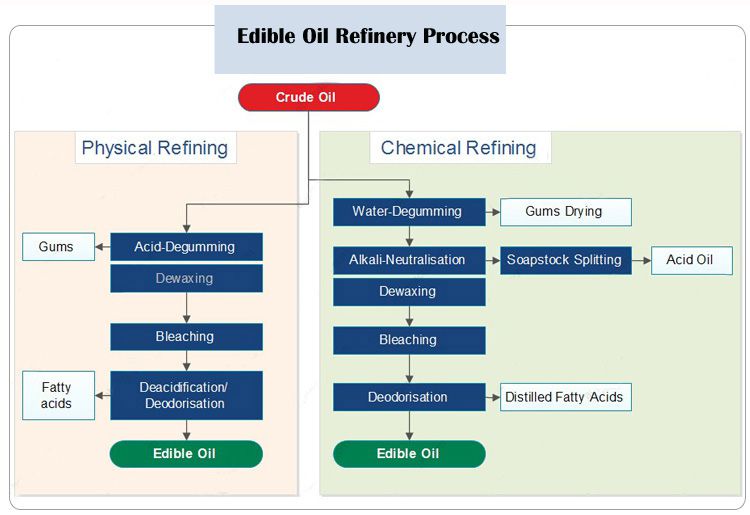

Before starting the oil refining, the crude oil must be filtered to remove the suspended solid materials, mainly oil cake residue, sand, fiber, etc. And some of the desolution materials, which are accumulated during the oil extraction or leaching process. Then, the crude oil can be refined. The oil refining process sequentially include degumming, deacidification, decolorizing, deodorization, dewaxing and more.

- Degumming: Remove the soluble impurities, such as phospholipids, in the crude oil. Hydrated degumming is the widely used method.

- Deacidification: Remove free fatty acids from crude oil. We usually adopts alkali refining method since alkali refining has the comprehensive function of deacidification, degumming, deimpurity and decolorization.

- Decolorizing: Remove the colors and pigments in the crude oil. Active white clay or active carbon is usually used in the process.

- Deodorizing: Remove the odors in the oil. This process usually adopts heating deodorizing.

- Dewaxing: Remove the wax in the crude oil. Not all the edible oil refining requires dewaxing process, only some vegetable oil that contains high content of wax should be dewaxed, such as crude sunflower oil.

Every oil refining process has respective oil refining equipment and they are a complete set of edible oil refining production equipment.

Additionally, in order to meet some cooking oil production plant without steam stove and the requirements of deodorizing process, Heat Conducting Oil Furnace is specially designed for edible oil refining. The heat conducting oil furnace can be heated with coal, natural gas, heavy oil and electricity as heat source. After heating, the temperature of heat conducting oil can reach above 300℃. On one hand, this heat conducting oil can indirectly supply hot energy for the whole oil refining process. On the other hand, it can heat water to vapour through steam generator.

Steam Generator is used to produce vapour, use heat conducting oil as heat source, make water changing to vapour. The beginning of the operation, flood soft water into the generator, then use heat-transfer oil(indirectly) to heat. Vapour at the pressure of 0.4Mpa can be supplied for deodorizing or other oil refining process.

Vegetable Oils and Animal Oils Available of Oil Refining

Vegetable Oils: soybean oil, sunflower oil, canola oil, mustard oil, cottonseed oil, palm oil, palm kernel oil, coconut oil, groundnut/peanut oil, niger seed oil, castor oil,

Animal Oils: seal oil, fish oil and more.

Edible Oil Refining Plant Project Setup by ABC Machinery

The edible cooking oil refining machine developed by our company features unique and advanced technology, reliable performance, high degree of mechanization and advanced technology index. There are serialized products and reasonable combination can be made according to the requirements of oil using purpose. The newly developed complete set of small-sized refining equipment (with capacity of 1~20t/day) combines a variety of individual equipment. The equipment itself is equipped with heat source and does not need to purchase steam boilers. This equipment can be used for many purposes to produce high quality edible oil, high grade cooking oil, salad oil. It is the ideal equipment for oil refining.

Build Your Future!

Build Your Future!