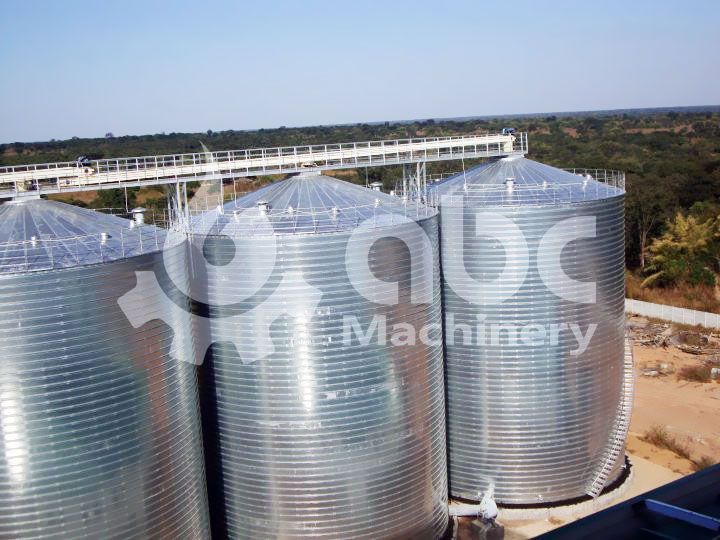

Project Name: Corn / Maize, Soybean Storage Silo

Project Location: Zambia

Year of Construction: 2011

Capacity: 2,500T*6

Storage grain: Store local soyabean and corn for oil milling and animal feed production.

Inside system: Ventilatoin system, temperature measurement.

This client build this grain storage plant for corn and soya beans. The corn is prepared for animal feed manufacturing and the soybean is used for soybean oil production plant. This is a turnkye project including design, equipment manufacturing and grain silo installation. This grain storage plant is assembled with temperature measuring device. The operator can turn on the fan below to lower it down once inner temperature exceeds set degree.

A grain silo is a large container used to store and preserve grain produce. Grain silos are also known as a grain bin, or grain storage silo. The grain storage containers range from small subsistence granaries to large commercial silos. Grain silos are used to preserve agricultural produce for longer periods after harvest. The common grains stored in the granaries include rice, corn, beans, peas, millet, wheat, barley, sorghum, soybeans, peanut seeds, rapeseeds, sunflower seeds, flour, animal feeds among other granular products.

There are different types of grain silos depending on the material used to build it. These include cement silos, plastic silos, timber silos, and steel silos. Spiral steel grain silos are the most common type of storage silo because of its outstanding and superior features.

Advantages of Our Grain Storage Silos

-

Leak proof containers

-

Built-in thermometer

-

Convenient and easy to operate

-

Meets customers requirements

We offer a wide variety grain storage silos meeting the individual customer's requirements including different sizes or design shape. Regardless of the type of the silo, our grain silos eliminate the risk of pesticides, insects, or chemical contamination.

Management of grain storage can proof to be very tedious and time-consuming since the stored grains require frequent inspection while regular maintenance of the silos is necessary when using the regular silos. However, when ABC Machinery grain storage silos are installed professionally, not only are they structurally strong and durable but they also save you from the tedious operations management. Chose ABC Machinery, chose durability and efficiency grain silo. Welcome inquire more details and latest cost!

-

Dear Sir/Madam, We need to store 8500 tons of cement. It needs to be in 6 silos with diameter of 8-10 meters each .There is a height limitation of 32 meters. There need to be a mixing option, for fly ash and slag. We need direct discharge point for each silo stores Portland cement (4 silos) and one discharge point for the mixing option. The silos that will not have any discharge point are for materials made only for mixing (fly ash and slag),We will load the silos with silo trailers. The final destination is providing cement to our concrete plants. You can look at the drawing above for first impression.

Can you plan and build something similar, with the capacity we need ? Thank you. -

Hi, Dear, Thanks for your enquiry to our products. As for your request, we suggest that you could have 6pcs ø10xH14m silo, considering that the specific gravity of cement is around 1.45g/cm3 FYI, I enclosed three kinds of silo drawings for your reference, please consider which one is best suitable for you

Please kindly check each drawings and let us have your final decision - I need quotation for 5,000 metric tons of silo galvanized, 20m dia x 24m tall, elevator, intake pit chain conveyor to the elevator, and chain conveyor to processing plant 30m away from the silo, sweep auger inside the silo. Please respond urgently. The silo will be installed in Sapele, Nigeria to carry dry corn.

-

Hi, thanks for your enquiry to our products. As for 5000 metric tons galvanized silo, do you want a 5000t silo, or two units of 2500t silo?

Besides, do you need grain cleaning sifter and dust collector? do you have dimension or drawings of site...?

We will suggest and design for you accordingly.

Build Your Future!

Build Your Future!