If you are looking or small wheat cleaning equipment unit or plan to set up your own wheat cleaning plant with limited budget, you are in theh right place! ABC Machinery should be your BEST choice! Due to quality and perfection finish machining capability, our grain processing equipment win high evaluation in the farm machinery market of both home and abroad. To warranty the high quality, all our machines are stringently checked on a range of parameters.

Two of Our Grain Seeds Cleaning Plant Projects

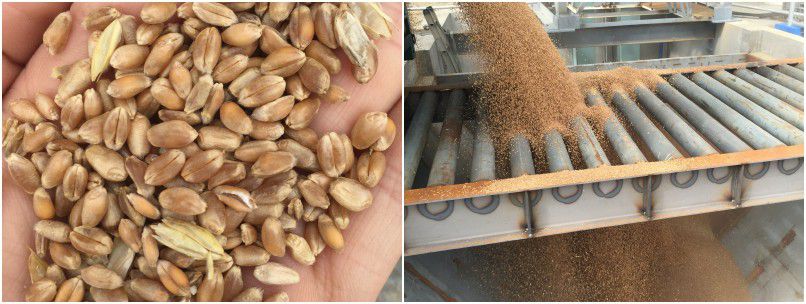

The seed, as small as it may appear, forms the basis of the agricultural industry which is the single largest industry on the planet. Regardless of the type of crop, the seed is essential for the development new plants which can be harvested accordingly. In addition, the seed itself can be harvested and used in numerous manufacturing processes. However, during the harvesting process, the produce from the field is usually contaminated with the inclusion of various impurities in the harvested stock. This has necessitated the development of processes that are geared towards recovering as many good seeds as possible from the harvest while considering the quality of the harvest and the efficiency of the process itself. Since wheat was one of the earliest crops to be domesticated by man, the wheat cleaning plant offers a perfect example to the steps involved in seed processing and the evolution over the years.

Main Process of Wheat Cleaning Plant

The initial process in a wheat cleaning plant is the cleaning and separation of the seeds. This stage is most crucial in determining the quality of the wheat seeds and the resultant products.

Wheat Cleaning Stage

The cleaning process seeks to get rid of the contaminants present in the seeds by eliminating any unwanted substances and retaining only the harvested seeds. The separation process further screens the cleaned seeds to remove the bad seeds that are considered unwholesome. Over time, the process of cleaning and sorting the harvested seeds has been mechanized through the use of industrial machines that take advantage of the physical and chemical properties of the seeds to provide a clean and pure harvest. It is however common for most machines to make use of several properties of the wheat to effect a more effective cleaning and sorting process. Sifters nowadays incorporate both vertical and horizontal sieving, aspiration and density separation in order to increase the amount of processed wheat per unit time and reduce both the cost and space involved in the process.

(Related Products: Grain Cleaning & Hulling Machines)

Wheat Conditioning Before Flour Milling

After guaranteeing that the sorted seeds are clean, the next process involves conditioning and treating the seeds. This process is necessary to guarantee that the seeds are ready to be milled and stored after further cleaning the seeds and completely drying them. The scalper is the seed conditioning and pre-cleaning machine of choice in most wheat processing plant.

Wheat Seeds Storage

Finally, the wheat cleaning process ends with the handling and storing of the processed seeds. These processes are essential for ensuring that the processed grain does not come into contact with contaminants again and ensure safe storage for future use. The main steps involved are the bagging, drying and additional cleaning of the seeds with the occasional addition of pesticides. (Related Projects: 1000 Tons Wheat Silo in New Zealand)

The important factor in any wheat cleaning plant is the arrangement of the facility. There exist several processing plant orientations that can be deployed depending on the type of machines in use, the available space and the initial financial investment. The main consideration should however be the sequential organization of the grain seeds cleaning plant. The overall design should take into account the arrival, sorting, cleaning, conditioning then handling and storing of the wheat. The end of one process should clearly mark the beginning of the next process without any unnecessary breaks.

Build Your Future!

Build Your Future!