For chicken farms, dealing with dirty and smelly chicken manure is a headache, and for investors who want to start an organic fertilizer production business, chicken manure is a valuable processing raw material. Build an organic fertilizer processing plant next to the farm to turn chicken manure into organic fertilizer, which not only reduces pollution, but also improves the economic benefits of the farm. So, for investors who are new to the field of organic fertilizer, how to build a small-scale chicken manure organic fertilizer processing plant at the least cost? Hope the following will clear up some of your confusion.

Build an Chicken Manure Organic Fertilizer Plant

How to make organic fertilizer pellets from chicken manure?

The organic fertilizer production line is to ferment, pulverize and sieve the animal manure organic wastes such as cow manure, sheep manure, pig manure, chicken manure, sludge, straw, corn stalk, add a certain amount of nitrogen fertilizer, phosphate fertilizer, potash fertilizer, magnesium sulfate and other substances, after fully mixing, processing it into organic fertilizer pellets through the pellet machinery.

Characteristics of processing chicken manure into organic fertilizer

- Provide comprehensive nutrition for crops. The organic fertilizer processed from chicken manure contains not only nitrogen, phosphorus and potassium, but also trace elements such as boron, zinc and molybdenum. After being applied to the soil, it can provide comprehensive nutrition for crops.

- Promote the reproduction of microorganisms. After the chicken manure is decomposed, it can provide energy and nutrients for the life activities of soil microorganisms, thereby promoting the reproduction of soil microorganisms. Microorganisms in turn accelerate the decomposition of organic matter through their activities and enrich the nutrients in the soil.

- Improve soil structure. After the chicken manure organic fertilizer is applied to the soil, it can effectively improve the water, fertilizer, gas and heat conditions of the soil, making the soil loose and fertile, which is conducive to cultivation and the growth and development of crop roots.

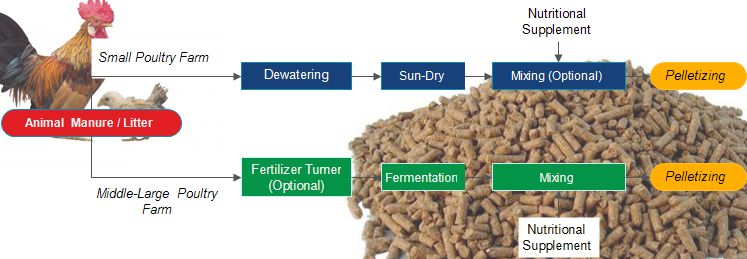

Chicken Manure Organic Fertilizer Production Process

Chicken manure organic fertilizer production line is a complete set of equipment to produce pure natural organic chemical manure through a series of production processes using chicken manure as raw material.The production of organic fertilizer pellets in chicken manure organic fertilizer processing plants must include 2 processes: early fermentation and pelletizing process.(You may want to know more about How to Make Organic Fertilizer from Cow Dung)

- Organic fertilizer fermentation raw material formula

The main material is chicken manure, and other auxiliary materials need to be added according to the moisture content to make it reach a suitable fermentation moisture content state. According to the requirements of each nutrient composition required by the final product, pay attention to the ratio of each material when adding auxiliary materials, so that when the fermentation of the material is completed, it is a qualified product, and there is no need to add ingredients again.

- Fermentation process of organic fertilizer

Chicken manure fermentation tank is an environmental protection equipment, which utilizes the decomposition of microorganisms in nature. After about 7 days of continuous aerobic fermentation in a closed fermentation tank, the organic solid waste is fermented, deodorized and decomposed by microorganisms, then processed into bio-organic fertilizers that can be used in crops.

Chicken Manure Fertilizer Fermentation Tank

The advantage of the chicken manure fermentation tank is closed fermentation. The principle of high temperature aerobic fermentation is adopted to effectively ferment the organic matter in the fermentation tank. The efficiency of the fermentation tank is very high, which can meet the effect of daily feeding and fertilizer output. In terms of environmental protection, the organic fertilizer fermentation tank supplied by ABC Machinery has outstanding advantages, high processing efficiency, no peculiar smell in the fermentation process, and small footprint, which meets the requirements of environmental protection for aquaculture.

- Chicken manure organic fertilizer pellet production

If the fermented and decomposed organic fertilizer is sold as powder, it can be directly crushed and screened for packaging. But if you want to produce pellet fertilizer, the required process is relatively complicated. Since the formation of pellets relies on moisture to condense the powder materials together, in addition to the previous pulverization and granulation process, drying is required to remove the moisture, and the material is cooled to room temperature by a cooler, and finally the finished product is sieved. The chicken manure organic fertilizer pellets are finally packaged with an automatic packaging machine.

poultry manure organic fertilizer production process

In terms of production technology, the production process of organic fertilizer pellets is relatively complicated and requires a lot of processing equipment, but for the market, pellets are the mainstream product after all. Especially in the case of large-scale farming, organic fertilizer pellets are convenient for mechanized fertilization, and the demand is still very large.

Chicken Manure Organic Fertilizer Equipment Selection Skills

At present, organic fertilizer processing equipment has become the mainstream trend of the fertilizer processing industry. It is more important to choose a manufacturer of equipment that can produce a complete set of small and medium-sized organic fertilizer production lines, because the entire production line is produced by one manufacturer. In the long-term processing and running-in, a relatively complete production system has been formed, and the equipment can operate in good condition.

The old saying is, first determine whether the processed product is powder or granular organic fertilizer, the processing technology determines what equipment to purchase, and the size of the site determines the size of the investment organic fertilizer production line.The common practice is that the equipment manufacturer sends staff to plan the user's available building area and planned funds, so as to make the configuration selection of the production line. Therefore, it is very necessary to find a manufacturer with reliable technology for guidance in the planning stage.

The equipment process of small and medium-sized organic fertilizer production lines is basically divided into two types: powder and pellets. As an investor, not only must have a clear understanding of the production process of the entire organic fertilizer production line process, but also must be aware of the composition of equipment and accessories. . Whether it is the selection of fermentation equipment, granulation equipment or conveyors, we need to make reasonable choices according to the process, site and production capacity. (Related post:Top 10 Organic Fertilizer Manufacturers & Suppliers 2021>>)

Small-level Chicken Manure Organic Fertilizer Plant Working Video

ABC Machinery independently develops and produces a complete set of equipment such as fermentation equipment, drying equipment, granulation equipment, cooling equipment, packaging equipment suitable for the production of organic fertilizers and bio-organic fertilizers. If you are interested in starting your organic fertilizer plant and do not know how to configure your production line with the least cost, you can contact us and we will provide you with the most cost-effective processing solution to help your investment plan go smoothly.

Build Your Future!

Build Your Future!