With the rapid development of the livestock and poultry breeding industry, a large amount of manure and sewage are produced. The harmful elements in these manures are seriously exceeding the standard, and it is difficult to treat them with traditional methods of returning to the field. In response to this situation, people have developed an organic fertilizer production line with mobile, high-efficiency solid-liquid separation technology as the core and integrated supporting high-efficiency mixers, fermentation machines, pellet machines and other fertilizer production equipment.

Make Cow Manure Organic Fertilizer Pellet

The products produced by the organic fertilizer production line are made of chicken, pig manure, and cow manure as raw materials, and do not contain any chemical ingredients. In fact, cow manure contains a large number of nutrients required for crop growth, including 10%-20% crude protein and 1% -3% crude fat, 20%-30% nitrogen-free extract and 15%-30% crude fiber are very nutritious. After composting, the cow dung has achieved harmless and stable treatment, and has reached the basic conditions for the utilization of organic fertilizer resources. The use of organic fertilizer production and treatment technology can make cattle manure reach the level of commercialization, deepen the application effect, and expand the scope of use. So how to use cow dung to make organic fertilizer pellets to start a commercial business? Next, ABC Machinery will briefly introduce it. (Related post:How to Make Cheap Chicken Manure into Efficient and Safe Organic Fertilizer Pellets>>)

How to Make Organic Fertilizer From Cow Dung and Urine?

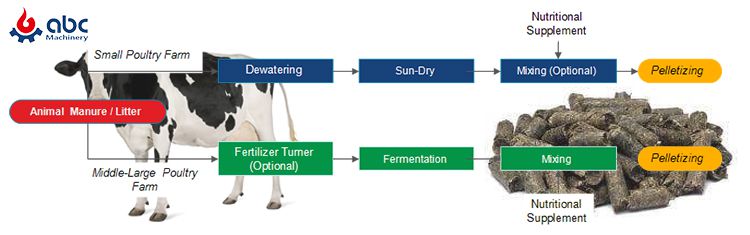

The production process of commercial cattle manure organic fertilizer mainly includes the steps of fermentation, crushing, mixing, granulation, drying, cooling and packaging. Generally speaking, the common production capacity of a single organic fertilizer production line is 1TPH-10TPH,because the output is too small, the economies of scale cannot be achieved, and the excessive output will increase the difficulty of the transportation and storage of raw materials and finished products.

Animal Manure Organic Fertilizer Production Process

- Fermentation and composting

Collect cow dung and cow urine and compost with hay and other organic agricultural waste to adjust moisture, ventilation, temperature, and carbon-nitrogen ratio. In the fermentation process, the fermentation tank equipment is used to achieve full fermentation through timely and uniform composting.

- Crushing and mixing of raw materials

The function of this stage is to use crushers and mixers to grind and mix raw materials. According to ABC Machinery's many years of experience in organic fertilizer production, the use of a vertical crusher can prevent the cow dung compost material from sticking to the wall of the machine, which is not easy to block.

- Pelletizing process

The crushed and mixed raw materials can be made into pellets by using the new organic fertilizer pellet making machine. The equipment has some obvious advantages, such as the wide adaptability of raw materials, especially for organic substances, without strict requirements on the density of raw materials and the fineness of crushing, and the stability of the finished pellets is good. The pellets produced by this organic fertilizer pellet machine are not easy to decompose.

Organic Fertilizer Ring Die Pellet Machine

Organic Fertilizer Pellet Mill

- Dry cooling process

The processed pellets are dried to remove moisture, so that the pellets meet the standard requirements of organic fertilizer moisture content. After the cooling process, the difference between the temperature of the particles and the temperature of the environment should be less than 5 degrees Celsius.

- Packaging process

After the pelletizing organic fertilizer is cooled, it can be weighed and packaged by an automatic fertilizer packaging machine, which greatly saves labor costs and improves the production efficiency of organic fertilizer.

The Main Advantages of Processing Cow Manure into Organic Fertilizer Equipment

Organic fertilizer equipment can quickly make cow dung into organic fertilizer pellets. Generally, the conventional operation and process of making organic fertilizer requires a long-term composting and fermentation of organic fertilizer, so as to realize the deodorization and fermentation of organic fertilizer in this process. The use of the fermentation equipment for processing cow dung into organic fertilizer can speed up the production process of organic fertilizer and realize the efficient fermentation of cow dung in a short time.

With abundant organic matter, the processing of cow dung into organic fertilizer pellets can provide a variety of micro-elements required by crops and improve the quality and yield of agricultural products. The organic manure produced by cow manure will rapidly multiply a large number of beneficial active bacteria, effectively inhibit the growth of harmful microorganisms, and at the same time produce various enzymes, promote the steady growth of crops, and enhance the resistance of crops to pests and diseases. In addition, it can effectively improve the physical and chemical properties of the soil, increase soil permeability, and greatly increase soil fertility.

Therefore, based on the above situation, in the future fertilizer market, organic fertilizer will occupy an important place, and the processing of organic fertilizer pellets from cow dung will also have a good room for development.Therefore, for investors who want to start a commercial business, building an organic fertilizer processing plant will gain a lot of benefits.

Build Your Future!

Build Your Future!