In cattle farming, roughage feed often determines both feed costs and the baseline for animal health. Efficiently turning readily available raw materials—such as hay, straw, and husks—into higher-performing and more stable feed is a practical concern for many producers. This article examines the characteristics of three common roughage types, analyzes cattle feed processing techniques and application value, and further introduces roughage pelletizing technology. This will help you decide whether to build your own cattle feed processing plant or invest in suitable feed machines to improve feed utilization.

How to Make Cattle Feed - Processing Guide and Machines

If you are considering how to maximize the efficiency of your existing raw materials for cattle feed making, contact us. We can provide equipment configuration and investment guidance based on your specific situation.

Characteristics and Processing of 3 Types of Cattle Roughage

Roughage for livestock refers to feed containing more than 18% crude fiber in dry matter, including green hay, straw, and husks.

I. Hay: The Foundation of High-Quality Cattle Roughage

Among all roughage types, hay is often regarded as the "cornerstone" of cattle diets. This is because it provides both palatability and nutritional stability. High-quality hay can contain 7%–21% crude protein, with legume hay at the top, and its cellulose and carotene content also ensure healthy growth for cattle.

However, many producers overlook the importance of "harvest timing" when making hay. Harvest too early and moisture is high, causing mold during drying; harvest too late and nutrient content declines. Experience shows that harvesting grasses from heading to flowering stage, and legumes from bud to 1/10 bloom, is optimal. During drying, avoid rain and mechanical damage to prevent significant losses of protein and vitamins.

II. Straw: Abundant but Low-Quality Roughage

Straw is one of the most readily available raw materials in rural areas, but it has significant drawbacks: crude fiber content can reach 30%–45%, with high lignin and low protein and energy content. Feeding it alone results in poor digestibility and low intake by cattle.

This is why straw requires processing. Common methods include:

- Ammoniation: Adding urea or ammonia water and sealing for fermentation softens the straw, produces a pleasant aroma, and significantly improves digestibility. Typical ratio: feed:water:urea = 100:(30–40):(3.5–4.5), fermented for ~1 month.

- Microbial Fermentation: Adding lactic acid bacteria or fungi with small amounts of sugar and salt results in softer, slightly acidic, and more palatable straw.

For investors, straw processing requires choppers, fermentation pits (or silos), and mixing equipment. These steps determine the final feed digestibility and directly impact cattle production performance. If you plan to use straw as a primary raw material, it is advisable to evaluate the investment differences between ammoniation and fermentation equipment in advance.

Start Profitable Cattle Roughage Feed Mill Business

III. Husks: Roughage Potential of Agricultural Byproducts

Husks (such as rice husks, wheat husks, or peanut shells) are often treated as waste, but in cattle feed, they can reduce costs and provide fiber. With cellulose content over 70%, husks offer sufficient roughage to stimulate rumen function.

However, husks require careful handling:

- Controlled inclusion: Keep within 5%–15%; excessive amounts make feed too coarse and reduce intake.

- Balanced mixing: Mixing with corn straw at a 1:1 ratio balances nutrients and ensures proper protein and energy levels.

- Cost reduction: Field data shows that reasonable husk inclusion can lower feed costs per head by 5%–10%.

For feed processing plant builders, husks are valuable due to low price and stable supply. Locating near rice or peanut production areas reduces procurement costs and, combined with pelletizing technology, enhances market competitiveness.

Raw Material Comparison Table: Key Parameters of Three Roughages

| Raw Material | Crude Protein Content | Crude Fiber Content | Main Advantages | Main Limitations | Common Processing Methods |

|---|---|---|---|---|---|

| Hay | 7%–21% | 20%–30% | Good palatability, balanced nutrition | Highly affected by harvest and drying | Drying, baling, crushing and pelleting |

| Straw | 2%–4% | 30%–45% | Abundant, low cost | Poor digestibility, low nutrition | Ammoniation, fermentation, chopping then pelleting |

| Husks | 3%–5% | >70% | Low cost, stable supply | Too coarse if overused, poor palatability | Crushing, blending with feed, pelleting |

Unsure which raw material is best for your farm or feed mill plant? Contact us for guidance on cattle feed formulation and processing solutions.

Cattle Roughage Pelletizing: Key Technology to Improve Feed Utilization and Palatability

After understanding the characteristics of hay, straw, and husks, many farmers and investors face a common question: these materials are plentiful but vary in nutrition and palatability, and feeding them directly often yields limited results. In this case, feed pelletizing becomes a critical step to consider.

Why Pelletize Roughage Feed?

For example, loose forage on a farm is easily sorted and trampled by cattle, with waste rates often exceeding 10%. Feed pellets ensure uniform intake and significantly reduce losses. Pelletizing also:

- Improves palatability: Moderate hardness prevents cattle from rejecting coarse straw or hard husks;

- Enhances nutritional balance: Crushed, mixed, and pressed, every bite contains the same formula;

- Facilitates storage and transport: Volume reduces by ~1/3, density increases, aiding long-distance shipping and long-term storage.

Cattle Feed Pellet Production Process

Pelletizing is not just “pressing grass” but a multi-step process:

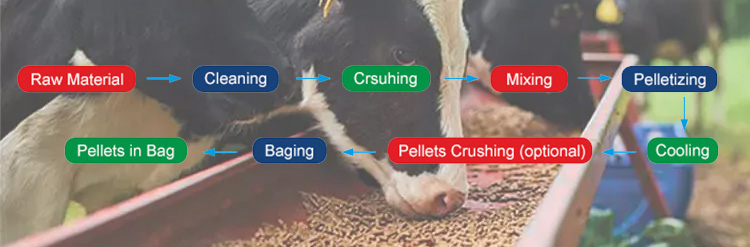

General Cattle Pellet Feed Production Process Flow

- Crushing: Chop hay, straw, and husks to 2–5 mm to improve compression;

- Pre-treatment: Low-quality straw often undergoes ammoniation or fermentation to ensure digestibility;

- Mixing and formulation: Add corn meal, soybean meal, and trace elements according to cattle growth stage;

- Conditioning: Use steam to soften fibers, increase pellet hardness and formation rate;

- Pelletizing: Feed into ring die or flat die feed pellet mill machines to produce 6–10 mm diameter pellets;

- Cooling and screening: Prevent moisture, mold, and remove dust and substandard pellets;

- Packaging and storage: Bagged or bulk, convenient for transport and feeding.

Equipment and process configuration at each feed pellet making process steps greatly affect final quality. If you want a complete flowchart and equipment list, contact us.

Application Scenarios for Farms and Feed Pellet Mill Plants

- Small and Medium Animal Farms: A self-use pellet machine (200–500 kg/hr) is sufficient. Advantages include flexibility, low investment, utilization of crop by-products, and reduced purchased feed costs.

- Regional Feed Pellet Plants: For external sales, a complete pellet production line (20–200 tons/day) is needed. Core investments include not only equipment but also plant layout, raw material storage, and automated packaging to ensure scalable supply.

Small Cattle Feed Mill Machine, 1-2 TPH Livestock Feed Manufacturing Plant

Therefore, when deciding whether to start a roughage pelletizing project, investors should clarify: Is the goal to feed your own herd, or to become a regional supplier? This will directly determine plant scale and equipment selection.

Build Your Future!

Build Your Future!