Poultry Feed Ingredient Overview

Functional Roles of Poultry Feed Ingredients in Modern Formulation Strategies

The foundation of poultry feed formulation relies on understanding how each poultry feed ingredient contributes to nutrient supply, metabolic efficiency, and production targets. Typical diet structures include 50–60% energy sources (corn, wheat, sorghum), 20–30% protein materials (soybean meal, rapeseed meal, fish meal), and 1–3% functional additives(vitamins, minerals, enzymes) that collectively support consistent flock performance across broiler chicken, layer, and breeder operations. (Related Post: The Best Chicken Feed Formulation>>)

Energy Ingredients and Their Metabolic Contribution

Corn, wheat, and sorghum supply 3,200–3,400 kcal/kg of metabolizable energy, forming the largest proportion of ration mass. A 1% shift in corn moisture (from 12% to 13%) affects energy density by nearly 20 kcal/kg, influencing feed conversion ratios. Ingredient variability of ±2% in starch content can alter pellet durability by 3–5%, showing the direct connection between nutrient composition and processing behavior.

Protein Sources and Amino Acid Availability

Soybean meal for poultry feed with 44–48% crude protein remains the primary source, but digestible lysine and methionine levels—typically 2.8–3.1% and 0.6–0.7%—drive growth performance. Bone meal contributes 12–14% phosphorus and 20–22% calcium, supporting skeletal development and eggshell quality. Even a 0.1% imbalance in digestible amino acids may reduce daily gain by up to 2 g in fast-growing broilers.

Functional Additives Enhancing Health and Efficiency

Additives such as enzymes, vitamins, trace minerals, emulsifiers, and organic acids typically occupy less than 2% of total inclusion but significantly influence immunity, gut health, and nutrient release. Vitamin premixes often contain 20–30 individual components, with precise dosing down to mg/kg levels.

| Ingredient Type | Key Nutrients | Typical Inclusion (%) | Technical Function |

|---|---|---|---|

| Corn | Starch, energy | 50–60 | Energy supply, pelletability |

| Soybean Meal | Protein, amino acids | 20–30 | Growth, tissue development |

| Bone Meal | Ca, P | 1–3 | Bone strength, eggshell |

| Vitamins | Micro-nutrients | 0.1–0.3 | Immunity, metabolism |

| Enzymes | Phytase, xylanase | 0.01–0.05 | Nutrient release |

Main Raw Material for Poultry Feed Making

Ingredient selection also depends on how materials behave during grinding, mixing, and pelleting. Corn with 600–700 g/L bulk density ensures stable die compression, while soybean meal with fine particle size (below 500 microns) improves mixing uniformity by 12–18%. The use of NIR (Near-Infrared Reflectance) enables real-time nutrient profiling, reducing formulation errors by 1–2 points in metabolizable energy estimation.

Micro-Ingredient Integration in High-Performance Diets

- Micro-Ingredient Distribution Small-inclusion materials such as enzymes and vitamins must be pre-mixed at 1:5 or 1:10 ratios to avoid clustering and segregation.

- Impact on Formulation Targets A 15–20% improvement in nutrient release from enzyme use reduces total diet cost by 2–4 USD/ton.

Partner with us to develop a nutrition-driven feed mill strategy that maximizes your flock’s potential and your plant’s efficiency.

How Ingredient Characteristics Influence Feed Mill Process Optimization

Ingredient physical properties—crushability, conditioning response, oil content, and fiber level—directly shape grinding efficiency, mixing homogeneity, and pelleting performance. The interaction between the poultry feed ingredient type and die compression ratio affects pellet durability by 5–10%. Moisture content also influences conditioning time; ingredients with lower moisture (<11%) often require 3–5 additional seconds in the conditioner.

Using appropriate ingredient impact on feed processing strategies enables mills to optimize workflow. Adjusting hammer mill sieve size from 3 mm to 2.5 mm can improve surface area by 15%, enhancing starch gelatinization during conditioning. Process engineers often adapt feed pelleting optimization by raw materials to ensure stable throughput above 15 t/h.

Get your customized feed mill processing optimization plan – Contact us now.

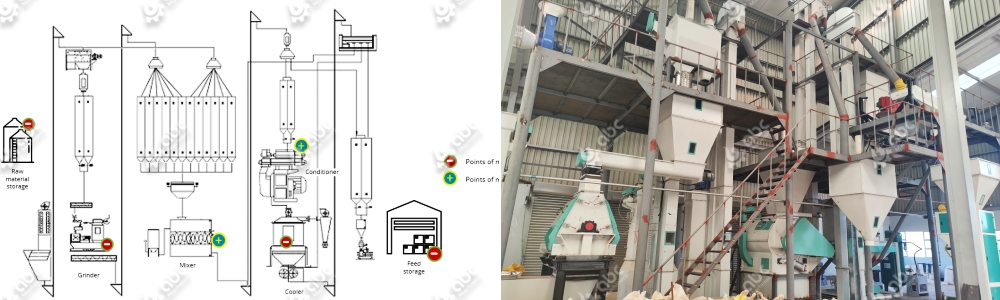

Poultry Feed Processing Plant Equipment Layout Design

Ingredient Sourcing, Cost Control, and Alternative Materials Strategy

Procurement teams must balance nutrient density, price volatility, logistics cost, and supplier stability. A 10 USD/ton fluctuation in soybean meal price can change total diet cost by 6–8 USD/ton. Effective poultry feed ingredient sourcing strategy requires analyzing seasonal availability, transportation lead time (often 7–10 days), and storage stability. (Read More: Cost of Starting A Profitable Poultry Feed Mill Business>>)

Cost management includes evaluating ingredient substitution models—such as replacing 10% corn with wheat or sorghum—without compromising nutritional consistency. The use of MES (Manufacturing Execution System) allows real-time cost modeling and traceable inventory control, reducing wastage by 3–5%.

Alternative raw materials for poultry feed such as rice bran, DDGS, or sunflower meal support flexibility when major commodities experience price spikes. Integrated feed ingredient cost management helps maintain competitive production costs even when market volatility is high.

Work with our formulation and procurement specialists to build a resilient feed ingredient strategy tailored to your plant.

Quality Control of Poultry Feed Ingredients and Risk Management

Consistent ingredient quality determines overall feed consistency and poultry health. Typical QC protocols monitor nutrient composition, particle size, moisture (normally 10–13%), impurities (<1%), and mycotoxin levels using NIR and rapid-test kits. The key poultry feed ingredient quality control steps involve screening for aflatoxins (limit <20 ppb), fumonisins, and DON to avoid intestinal damage. Feed material contamination risks increase significantly when moisture exceeds 14%, accelerating mold growth by 15–20%.

Raw material acceptance criteria typically require suppliers to meet defined nutrient ranges, traceability documentation, and batch-level QC reports.

At the core of every efficient production system is a well-structured poultry feed formulation, supported by precise ingredient selection and consistent control of every poultry feed ingredient used throughout the process.

Build Your Future!

Build Your Future!