Broiler Chicken Feed Manufacturing For Fast Weight Gain

Typical Broiler Feed Formulations (Practical Examples)

Broiler feeds focus on high energy, balanced amino acids, and stable gut function. Below are practical formula snapshots used by many commercial farms—each with a different cost and growth focus.

- Cost-Effective Starter Formula (0–14 Days): 50–55% Corn, 28–32% Soybean Meal, 3–5% Wheat Bran, 3–4% Soybean Oil, 3–5% Fish Meal/MBM, 1.6–1.8% DCP, 1.2–1.4% Limestone, 0.5% Premix, 0.25–0.35% Methionine + Lysine

- High-Energy Grower Formula (14–28 Days): 58–62% Corn, 22–26% Soybean Meal, 5–8% Wheat/Broken Rice, 2–3% Animal Protein, 4–5% Soybean Oil, 1.0–1.2% Limestone, 1.3–1.5% DCP, 0.5% Premix, 0.2–0.3% Amino Acids

- Low-Cost Finisher Formula (28 Days to Market): 60–65% Corn, 18–22% Soybean Meal, 8–12% Wheat Bran/DDGS, 3–4% Oil/Fat, 1.0% Limestone, 1.0–1.2% DCP, 0.5% Premix, 0.15–0.25% Met + Lys

Broiler Feed Formulation Nutritional Requirements For Fast Growth

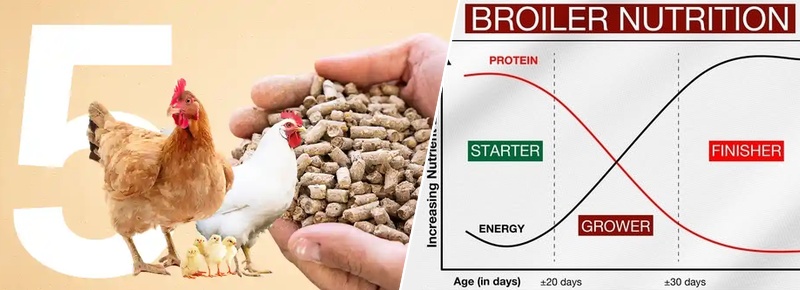

The core of broiler chicken feed formulation is understanding what birds need at each growth stage and then converting those needs into practical ingredient ratios. In commercial poultry feed production, farms usually target an FCR of 1.55–1.70 by day 42 and adjust metabolizable energy (ME) to 2,950–3,150 kcal/kg based on the growth phase. These targets determine how energy, protein, and key amino acids are allocated across the starter, grower, and finisher diets.

Broiler Nutrition Requirements Change in Full Growth Stage

Energy–Protein Balancing For Broiler Performance

Energy density has a direct influence on feed intake. For instance, reducing ME by 100 kcal/kg can increase intake by 4–6%, which may raise total feed costs by 3–5%. Starter diets generally require 21–23% crude protein, while finisher diets can drop to 18–19% depending on carcass yield targets. Maintaining a lysine-to-crude protein ratio of 5.8–6.2% is essential for ensuring muscle deposition efficiency. Threonine and methionine—two limiting amino acids—must be maintained within ±0.05% of ideal ratios to prevent performance losses.

Mapping Nutrient Targets Into Industrial Formulation

Feed formulators use linear programming models to convert nutrient requirements into ingredient proportions. For broilers, corn typically contributes 55–65% of the formula, soybean meal contributes 20–28%, and fat sources add 2–4% depending on energy targets. Two common methods are:

Linear Programming With Nutrition Matrices

This method uses ingredient nutrient matrices containing more than 40 analytical values such as ME, crude fiber, and digestible amino acids. Adjusting the matrix by even 1–2% for moisture variation can shift total diet cost by USD 3–6 per ton.

Dynamic Formulation Based On Real-Time NIR

Near-Infrared Reflectance (NIR) systems allow mills to continuously analyze raw material quality. With scan speeds under 20 seconds and accuracy within ±0.2% for protein prediction, mills can instantly adjust ingredient ratios to maintain target nutrient levels.

Key Data Ranges In Broiler Formulation

| Parameter | Starter Phase | Grower Phase | Finisher Phase |

|---|---|---|---|

| ME (kcal/kg) | 2,950–3,050 | 3,000–3,100 | 3,100–3,150 |

| Crude Protein (%) | 21–23 | 19–21 | 18–19 |

| Digestible Lysine (%) | 1.20–1.35 | 1.05–1.15 | 0.92–1.00 |

| Calcium (%) | 0.90–1.00 | 0.80–0.90 | 0.70–0.80 |

Starter broilers consume 0.35–0.45 kg of feed per day during the first week, increasing to 1.2–1.4 kg per day by week five. These intake patterns dictate energy and amino acid concentration across formulas to maintain growth rates of 55–65 grams per day in early phases and 80–95 grams per day in the final phase.

Drive measurable improvements in nutrition-driven feed mills — Connect with our formulation engineering team to build data-backed broiler feed strategies.

Implementation Strategies In Broiler Feed Production Line Design

Making Broiler Feed at Home Using Small Mill Machine

Integrating broiler feed formulation principles into a physical processing line requires coordinated engineering across grinding, mixing, conditioning, and pelleting. When designing a chicken feed mill plant, two processing variables—particle size and mixing time—have the greatest impact on nutrient distribution. For example, reducing particle size from 900 microns to 650 microns can improve pellet durability by 6–10% and increase digestibility by 2–3%.

Pellet mills operating at 3–6 tons/hour require conditioners capable of achieving 75–82°C mash temperature and at least 35–45 seconds of retention for proper starch gelatinization. These values are critical because a 2°C drop in temperature can reduce pellet quality index (PDI) by 3–4 points. Maintaining mixer coefficient of variation (CV) below 10% ensures consistency of amino acids and micro-ingredients across every batch.

Partner with us to integrate nutrition-driven design into your broiler feed production line and strengthen plant-wide performance.

Broiler Feed Formula Raw Material Selection And Cost Optimization Model

Selecting cost-effective chicken feed ingredients is essential for maintaining formulation efficiency under fluctuating commodity markets. Soybean meal often varies by USD 20–40 per ton across seasons, while corn prices may shift by 5–12% depending on regional harvest conditions. A robust cost model evaluates energy contribution per dollar, amino acid yield per ton, and transportation distance in kilometers.

Mills commonly replace 3–6% of corn with wheat or sorghum depending on regional availability, and substitute 2–4% of soybean meal with canola meal when protein spreads exceed USD 35 per ton. Work with our procurement engineers to build a raw-material cost model aligned with your plant’s supply chain conditions.

You May Interested in: Cost of Starting A Chicken Feed Mill Business>>

Quality Control And Performance Monitoring Of Finished Broiler Feed

Quality assurance in broiler feed production hinges on measuring physical and nutritional indicators at each batch. Particle size should remain within 600–900 microns for balanced digestibility and pelleting efficiency, while final moisture should stay between 10.5–12.5% to maintain a 2–3 month shelf life. Pellet durability index (PDI) is typically targeted at 88–92 to control fines under 4–6%. Sampling frequency is usually set at every 25–30 tons of finished product made.

Modern mills use MES (Manufacturing Execution System) platforms to track parameters such as batch weight, mixing CV, conditioning temperature, and pellet mill load percentage. Plants processing 150–200 tons per day typically improve yield by 2–4% after integrating MES-based data tracking.

Broiler performance monitoring links feed quality to flock output. Weight targets of 1.6–1.8 kg at day 28 and 2.4–2.6 kg at day 35 are widely used commercial benchmarks. Mortality rates should remain below 3.5%, with FCR maintained at 1.55–1.70 across flocks. Ensure reliable feed quality and flock performance — Contact our team to implement a precision-driven QC framework in your plant.

At the intersection of engineering, nutrition, and cost management, advanced broiler feed formulation strengthens overall plant output while aligning with broader poultry feed formulation objectives for consistent production, predictable cost, and optimized flock performance.

Build Your Future!

Build Your Future!