What is Silage Feed?

Silage feed is a high-moisture fodder produced through anaerobic fermentation of fresh materials such as pasture grass, corn stalks, and legume forages. The process uses lactic acid bacteria fermentation under airtight conditions. High-quality silage appears green or yellow-green, is soft and moist, has fruity or fermented aroma, fine fiber, and is rich in vitamins, calcium, and organic acids, which aid in cattle digestion and nutrient absorption.

Start Silage Feed Production for Cattle

In beef and dairy production, silage effectively addresses seasonal shortages of fresh grass while enhancing palatability and nutrient utilization through fermentation. Compared to direct straw feeding, silage reduces waste and lowers feeding costs, making it a common roughage choice for large-scale farms and feed mill projects.

For readers planning to expand their livestock operations or invest in a feed mill plant, mastering how to make silage for cattle is a crucial step. This article systematically explains high-efficiency methods for making green fodder for cattle, covering raw material selection, production processes, and pellet feed processing solutions, helping you identify feasible paths and make informed equipment selection and investment decisions.

Comparison of Common Silage Raw Materials for Cattle

The following table shows nutritional differences among typical silage ingredients:

| Raw Material | Dry Matter (%) | Protein (%) | Fiber (%) | Crude Fat (%) | Ash (%) | Calcium (%) | Phosphorus (%) | Potassium (%) | Energy (MJ/kg) |

|---|---|---|---|---|---|---|---|---|---|

| Corn Silage | 25–35 | 8–12 | 25–35 | 1–3 | 1.5–2.5 | 0.2–0.4 | 0.2–0.3 | 0.8–1.2 | 8–10 |

| Purple Alfalfa Silage | 20–30 | 15–22 | 25–30 | 1–2 | 10–15 | 1.2–1.7 | 0.2–0.4 | 2–3 | 10–12 |

| Alfalfa Silage | 15–25 | 18–28 | 25–32 | 1–2 | 8–12 | 1.2–1.8 | 0.2–0.4 | 2–3 | 10–12 |

| Sorghum Silage | 30–40 | 5–10 | 30–40 | 1–3 | 4–7 | 0.3–0.6 | 0.2–0.4 | 0.8–1.5 | 7–9 |

| Pasture Grass Silage | 20–35 | 8–20 | 25–35 | 1–5 | 6–15 | 0.5–1.5 | 0.2–0.5 | 1–4 | 8–10 |

| Soybean Silage | 25–35 | 15–25 | 25–35 | 1–3 | 5–8 | 0.3–0.5 | 0.2–0.4 | 1–2 | 10–12 |

| Wheat Silage | 20–30 | 8–15 | 25–35 | 1–2 | 1.5–2.5 | 0.2–0.4 | 0.2–0.3 | 0.8–1.2 | 7–9 |

When setting up a cattle feed mill or designing feed formulas, local raw material availability and livestock goals must be considered. For example, corn silage is high in energy and ferments reliably, making it the top choice for most farms, while alfalfa provides high protein but may require mixing with grasses or corn for stable fermentation. If you have any questions about animal feed processing, contact our experts!

Making Process of Silage Feed for Cattle

The essence of silage making lies in controlling raw material moisture, chopping length, and anaerobic conditions. The general process is as follows:

Cattle Silage Making Process Flow

- Construct a pit or prepare airtight containers: Choose a high, well-drained site. Ensure the silo or container is sturdy and sealed.

- Harvest at the right stage: Corn at the wax stage, legume forage at budding or flowering, and grasses at boot stage.

- Chop the material: Chop grasses and legumes to 2–3 cm and corn stalks to 0.5–2 cm for easier compaction and fermentation.

- Fill and compact: Layer 20–30 cm at a time, pressing to minimize air pockets, especially at corners.

- Seal and ferment: Cover with plastic film and 30–40 cm of soil to prevent rain and maintain anaerobic conditions. Generally, 35–45 days of fermentation is sufficient.

Variations of Silage Processing Methods

- High-Moisture Silage: Moisture content above 70%. Forage is ensiled directly after harvest without drying. The process is simple and efficient, reducing field losses, but fermentation is often unstable and storage quality may decline.

- Semi-Dry Silage: Raw materials are pre-wilted to 40–55% moisture before ensiling. This method is especially suitable for legumes, which are prone to spoilage at higher moisture levels.

- Mixed Silage: Different feedstocks are combined to complement each other in nutrition and moisture content, improving fermentation success. Common examples include mixing corn stalks with alfalfa or legumes with grasses.

- Additive Silage: Nutritional or microbial additives are incorporated to improve fermentation and feed value. For instance, adding 0.5% urea to corn silage can increase crude protein by 8–14%. Other inoculants may also be used to promote lactic acid fermentation and reduce spoilage risks.

Tips for Application of Silage in Cattle Feeding

Although silage offers clear benefits, attention is needed during actual feeding:

- Balance with concentrates: Different raw materials vary in nutrients; adjust formulas according to energy and protein requirements.

- Introduce gradually: When first feeding, place a small amount of silage at the trough bottom and cover with concentrate to allow cattle to adapt.

- Special stage control: Pregnant cows may require reduced silage amounts to avoid digestive stress.

- Avoid feeding frozen silage: In winter, thaw frozen silage before feeding.

- Control daily intake: Adjust according to raw material quality and cattle size. Adult beef cattle: 20–40 kg/day; dairy cows: 25–50 kg/day.

Contact us for customized cattle feed processing formulas and production process design.

Regular Silage VS. Silage Pellet Feed Processing

Regular Silage

- Low cost, suitable for on-site storage and self-feeding;

- High management requirements—poor compaction or sealing can lead to mold;

- Limited transport radius, not suitable for long-distance sales.

Silage Pellet Feed (Recommended)

- Processed through drying, grinding, and pelleting, resulting in lower moisture for easier transport and long-term storage;

- No extra cutting needed during feeding, improving cattle intake;

- Higher investment required, needs complete machinery set (cattle feed grinder machine, mixer machine, pellet machine, cooling and packaging units);

- Better suited for feed mills or cooperatives with sales plans.

For investors, choosing silage pellet production reduces feeding risks, as pellets provide more controllable quality, uniformity, and stability. If your goal is large-scale commercial sales, silage pellets improve product standardization and market entry; for personal use, regular silage suffices.

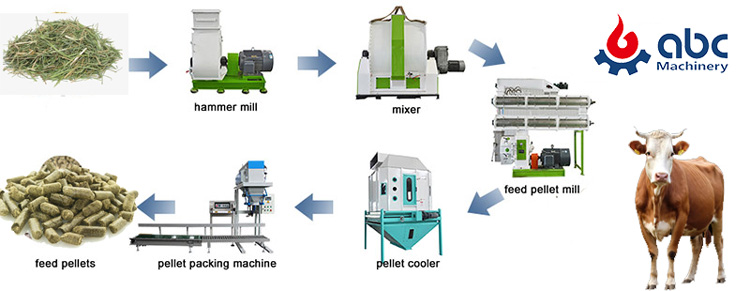

Cattle Feed Pellet Mill Machine Process Flow

ABC Machinery Provides Full-Process Support for Your Feed Mill Plant

Our company offers one-stop solutions for feed mill plant setup, from planning to operation, including capacity planning, factory layout and process design, equipment manufacturing, installation, and commissioning. We provide professional guidance and customized solutions to ensure smooth project execution.

We offer flexible modular designs for farms or enterprises of different scales, allowing capacity adjustments based on raw material supply and market demand, maximizing investment returns.

A 2-Ton-per-Hour Cattle Feed Pellet Plant Project

Buy Livestock Feed Processing Machine from Reliable Manufacturer/Supplier ABC Machinery

This project targets medium-sized farms or regional feed production needs, with a designed daily output of approximately 48–50 tons/day (24-hour continuous production) of pellet feed, meeting local market or self-use requirements. The modular design allows future expansion or processing of additional feed varieties.

The entire pellet feed production process includes raw material grinding, mixing, pelleting, cooling and sieving, and packaging.

Build Your Future!

Build Your Future!