Scraper conveyor is also named as drag conveyor. It is designed for conveying powder, granular, small block materials. It is suitable to deal with oilseeds, granulated sugar, beans and other gain materials. It is commonly applied in vegetable oil plant, oil extraction line and other oil pressing projects. The conveying speed is controlled by the rotating speed.

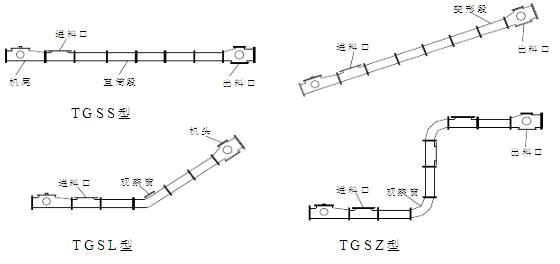

Scraper conveying machinery is featured of simple structure, good sealing, convenient in installation and maintenance, capable of horizontal, inclined and vertical transportation.

| Model | Capacity (t/h) | Speed (m/s) | Max Conveying Length (m) |

|---|---|---|---|

| TGSS16 | 10-20 | 0.2-0.4 | 50 |

| TGSS20 | 15-30 | 0.25-0.5 | 50 |

| TGSS25 | 25-50 | 0.3-0.5 | 60 |

| TGSS32 | 50-100 | 0.3-0.5 | 60 |

| TGSS40 | 100-200 | 0.4-0.6 | 70 |

| TGSS50 | 200-350 | 0.4-0.6 | 70 |

| TGSS63 | 350-500 | 0.5-0.7 | 80 |

| TGSS80 | 500-800 | 0.5-0.7 | 80 |

| TGSS100 | 800-1000 | 0.5-0.8 | 100 |

| TGSS160 | 1000-2000 | 0.5-0.8 | 100 |

Advantages of Using Screw Conveyor in Vegetable Oil Plant

Screw conveyor is featured of simple structure, small in size, good sealing, convenient in installation and maintenance, capable of horizontal, inclined and vertical transportation. It plays both the role of horizontal screw conveyor and bucket elevator. It flexible to process, can charging and discharging at optional position of machine body. Good sealing can prevent the dust in public and improve workers operating conditions. It is suitable for conveying of bulk, granular, powder and damp materials, such as oil seeds, cooked flake, oil cakes, and mill cakes in Vegetable Oil Processing Plant.

The Working Principle and Characteristics of Scraper Conveyor

Scraper (screw) conveyor is a kind of conveying equipment, with the moving of scraper chain in a closed rectangular housing, continuous sending bulk materials. Since the conveying process is based on the scraper chains, it is named scraper conveyor.

During horizontal transporting, under the combined action of pressure and gravity, inside friction produced between the materials. This inside friction can ensure the steady state of conveying materials and prevent rolling of raw materials during the conveying process. It can also overcome the external friction between the materials and the wall of closed trough, forming a continuous material flow.

During vertical transporting, under the pressure (up) of scraper chain, lateral pressure between the materials is produced, so as to form inside friction. Meanwhile, due to the continuous feeding of lower scraper, lower materials will produce continuous impetus to the upper materials. The friction force and impetus can overcome the gravity of the material itself and form a continuous material flow to sending the materials upwards.

Welcome to contact us by the below contacts form, if you have any questions about oil extraction, oil refining, or need more details our oil processing machines.

Build Your Future!

Build Your Future!