Refined Edible Oil Market Overview

Most edible oils are made from plants, like soybean oils, sunflower oils, groundnut oils, palm oils, olive oils, coconut oils, etc. These cooking oils are extracted through different oil milling technologies. The oils coming from oil pressing plant or solvent oil extraction plant is called crude oils, which contains a lot of impurities, like cake chips, colloidal impurities, free fatty acids, pigments and odour substances. Edible oil refining process is to remove all these unwanted and unhealthy substances to make vegetable oils more suitable for consumption and storage and increase its edible and market value.

Palm Oil

Soybean Oil

Canola/Rapeseed Oil

Sunflower Oil

Groundnut Oil

Cottonseed Oil

Edible oils segment is expected to generate revenues of USD 11.18 billion by 2022. The market is expected to grow at a rate of 4.51% per annum (CAGR 2022-2027). There are great and stable demand for high quality edible oils around the world. In order to enjoy more competive edges in cooking oil industry, it is necessary to equip your oil mill plant with professional oil refining equipment, or you can just start your own business by setting up an edible oil refinery plant.

Edible Oil Refining Types

≡ 1~30TPD Batch Type

≡ 30~50TPD Semi-continuous Type

≡ >50TPD Fully Continuous Type

The oil refining process is fully continuous, with high automation, high capacity, low labour costs and high quality final refined edible oils; It requires large investment compared with other types of oil refining machines. It is suitable for medium and large cooking oil mill projects.

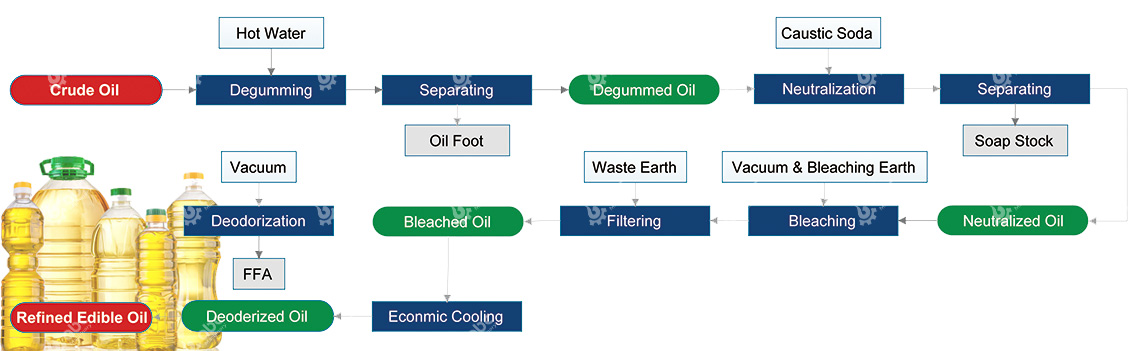

Edible Oil Refining Process

Edible oil refining is the collective name for a series of processes to remove solid impurities, free fatty acids, phospholipids, gums, waxes, colours, odours, etc. from vegetable oils. There is a standard refining process to produce high-quality edible oils. This is because it is important for an oil refining plant to ensure that they produce high quality oil products at all times. Meeting these standards is sometimes difficult due to the rapidly increasing demand for edible oil.

Edible Oil Refining Process Flow Chart

ABC Machinery has rich experiences in providing tailor-made edible oil refining solutions for edible oil milling business, from factory design to completed project installation and debugging, we have strong engineer team to help to solve all the technical problems.

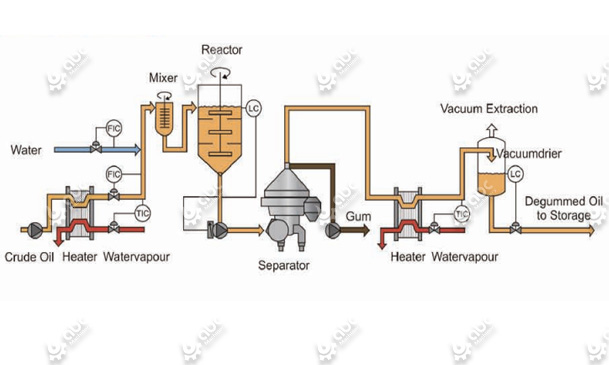

Edible Oil Degumming Process

Degumming

It is important to remove the "gums" because they have emulsifying properties. If not, the oil will become thermally unstable and can decompose.

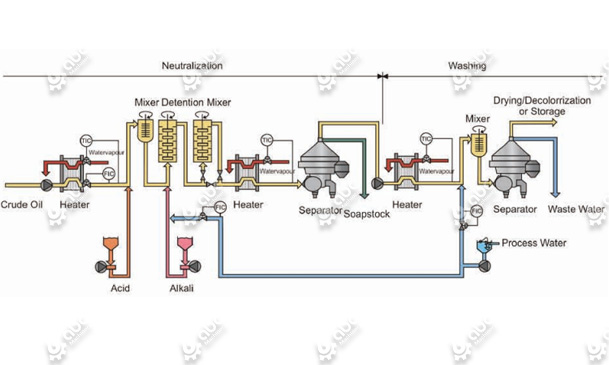

Neutralizing

Edible Oil Deacidification Process

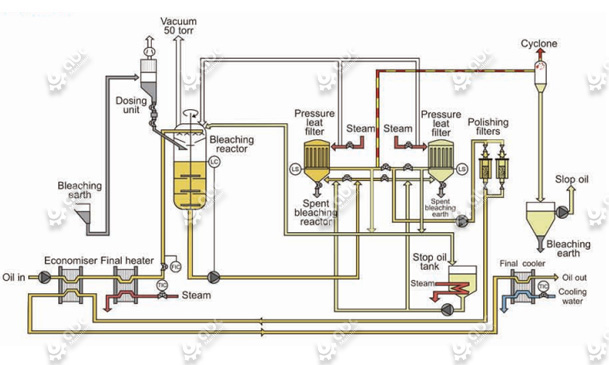

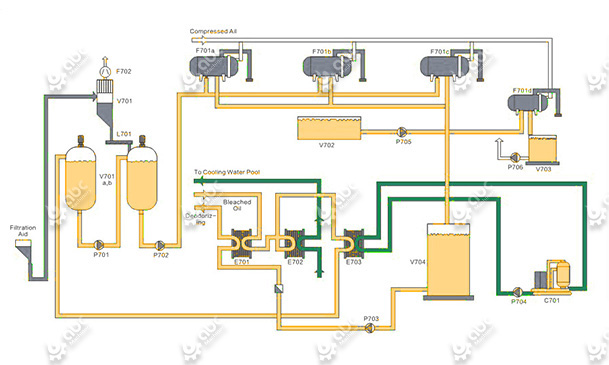

Edible Oil Decoloration Process

Bleaching

Deodorization

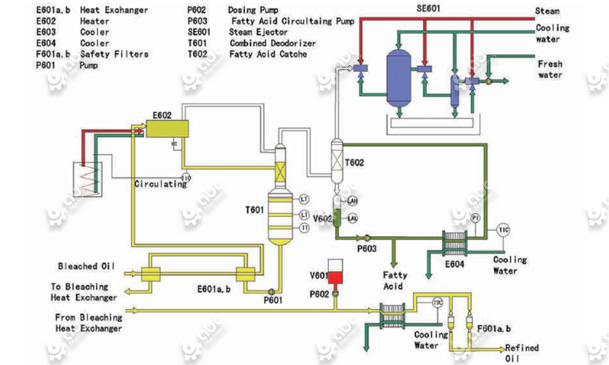

In this process, the oil passes through a high-vacuum steam and high-temperature distillation process. Doing this properly will remove volatile materials and off-flavors. Deodorization also removes fatty acids that remain after the neutralization process. This leads to the production of high quality edible oils with a long shelf life.

Edible Oil Deodorization Process

Edible Oil Dewaxing Process

Winterization

▎Finding Edible Oil Refining Solutions for Different Vegetable Oils

▎How to Calculate Edible Oil Refining Losses?

In terms of oil production cost control, edible oil refining equipment is required to remove the maximum amount of impurities, the minimum amount of oil loss, the minimum amount of drainage and the minimum amount of additives. It is therefore extremely important to know how to control the loss of oil. The losses incurred by the refining equipment in production are related to the impurities removed in each edible oil refining process, taking soybean oil as an example, the losses in each refining process are as follows:

➤ Filtration: 1.3~1.5 times the amount of suspended impurities

➤ Degumming: 1.5 times of phospholipid substances,1.65%~5.25% of the oil

➤ Deacidification: 1.05~1.2 times that of free fatty acids, about 2.1%~2.4% of the oil.

➤ Deodorization: 0.2%~0.4% of the oil.

➤ Decoloration: 0.15%~0.75% of the oil (depending on adsorbent)

✓ Simple Calculation: Total Oil Loss = Alkali refining loss + 0.6%

The above is oil loss by soybean oil refining process. But it is just for reference only. It should be calculated according to specific or the actual situation in production.

≡FAQ about Edible Oil Refinery

What's Crude Edible Oil Refining Methods? What's the Function of Palm Oil Fractionation Process? How to Choose the Right Refining Process?≡ Cost & Price on Edible Oil Refining

What's Edible Oil Refinery Plant Cost? What's Equipment Cost for Edible Oil Refining Business? TOP Edible Oil Refining Machine Manufacturer or Supplier≡ Technical Guidance of Oil Refinery

ABC Machinery offers custom-made solutions for edible oil refining plant design according to different requirements, raw materials and factory site. We have a professional technical team with 25 years of practical experience in design, manufacture, installation and commissioning. FREE and professional guidance are available.

Edible Oil Refining Plant Investment Business Plan

- In-Depth Market Research for High Demand Edible Oils;

- Get Licenses for Edible Oil Refining Business for Permission;

- Preparing Funds – Loan or Subsidies from Bank or Entrepreneurs;

- Confirm Capacity, Factroy Design, Equipment and Installation Details with Oil Refinery Machinery Supplier;

- Build Team for Factory Operation and Final Product Selling;

The edible oil industry is very profitable. It has low risk and a good return on investment. However, there is a lot of work for you to do to be successful. If you don't where and how to start it, just contact us, we are always happy to share with you professional information about edible oil refinery, which will help you to be well on your way to maximize profits of the edible oil refinery business.

Edible Oil Refining Plant Project

ABC Machinery has been contributing to the professional and technigical development of cooking oil milling field. We have undertaken many oil refining plant projects in different regions since the establishment in 1992. We have helped customers with edible oil refining projects setup and won their trust. As the core business of ABC Machinery, we never stop to update the equipment and technology of cooking oil refining with the aim to providing our customers with more reliable and less cost project. We have nearly hundreds of a model of successful projects, with rich designing, construction experience, strong strength and well-deserved reputation. With strong strength and good reputation, we have acculate rich practical experiences in designing and construction through successfully completed nearly hundreds of a model project in Australia, Mexic, Jameica, Pakistan, Zambia, etc.

Build Your Future!

Build Your Future!