The presence of impurities in sunflower seed crude oil not only affects the edible value and safe storage of the oil but also presents challenges in further processing. However, the goal of refining is not to remove all impurities from the oil but rather to eliminate those impurities that are harmful or undesirable for consumption, storage, industrial production, such as phospholipids, and moisture. At the same time, beneficial "impurities" like sterols and vitamins are intended to be retained. Therefore, based on different requirements and purposes, the aim is to remove unwanted and harmful impurities from sunflower seed crude oil to obtain a finished oil product that meets specific quality standards.

Start Crude Sunflower Oil Refining Plant

Introduction to Sunflower Oil Refining Steps

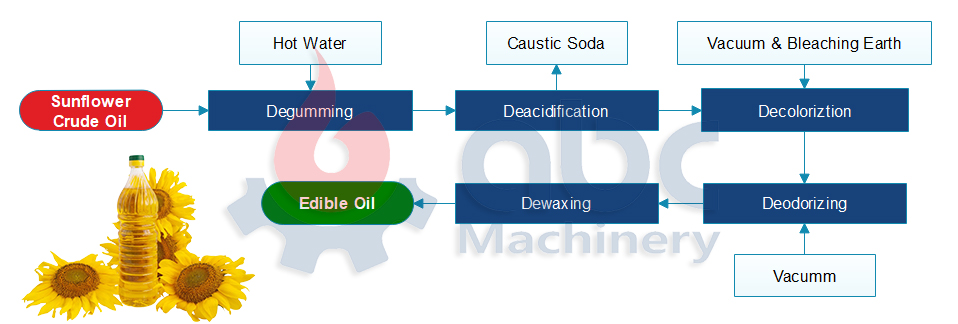

The refining process of sunflower seed oil mainly includes several stages: pretreatment, degumming, deacidification, decolorization, deodorization, and dewaxing.(Relaed Article: Sunflower Oil Refinery Plant Cost>>)

Flow Chart - Sunflower Oil Refining Process

- Pretreatment: The pretreatment stage involves sedimentation and filtration of the raw sunflower seed crude oil to remove large particles and impurities.

- Degumming Stage: Soluble impurities in crude sunflower oil not only affect stability of the oil but also the efficiency of oil refining and further processing.

- Deacidification Stage: This involves the removal of free fatty acids from sunflower seed oil through alkali refining or physical deacidification methods.

- Decolorization Stage: This aims to remove impurities and pigments from crude sunflower oil to achieve a lighter color.

- Deodorization Stage: This is mainly carried out through methods such as steam and vacuum distillation process to remove volatile components like free fatty acids and oxidation products from sunflower seed oil. This process reduces off-flavors, resulting in a milder and purer taste.

- Dewaxing Stage: Dewaxing primarily makes low-temperature crystallization or solvent crystallization methods to remove free waxes from sunflower seed crude oil. This prevents the oil from crystallizing and solidifying at low temperatures, preserving the desired flavor and texture of the oil.

Analyzing Sunflower Oil Refining Process Techniques: Batch, Semi-Continuous, Continuous

Low-cost Sunflower Oil Refining Machine for Sale

Batch Refining

Batch refining peocessing line offers superior production cost-effectiveness and efficiency compared to similar products in the industry, making it the ideal choice for small to medium-sized sunflower oil refining process plants. Batch Refining equipment features the following characteristics:

- Suitable for refining small-tonnage (1-30ton) crude oil.

- Requires lower investment, easy operation, and a smaller footprint.

- Low electricity and equipment maintenance costs, allowing for flexible production batch and output adjustments as per production needs. It can also adapt to peak electricity demand during different seasons and regions, ensuring timely avoidance of peak power usage.

-

The refined oil quality surpasses that of competitors.

Semi-continuous Refining

Semi-continuous refining processing line serves a wide range of small to medium-sized sunflower oil plants. Through years of research and development, semi-continuous refining has become better suited for small to medium-tonnage(10-50ton) sunflower oil refining prodcution. The equipment offers the following advantages:(Read More: 50t/d Fish Oil Refinery Plant in Pakistan>>)

- Simple auxiliary equipment, reliable operation.

- Low electricity consumption, higher refining efficiency compared to batch and traditional semi-continuous processes, improving refining production by about 1% compared to batch refining.

- Stable oil quality and strong adaptability to different types of oils, suitable for refining various oil and fat varieties.

-

Enhance the operating environment of oil factory and increase their profit efficiency.

Continuous Refining

Continuous refining processing line is designed for businesses with at least thirty days of continuous full-load sunflower oil production cycles. ABC continuous refining technology possesses design the following characteristics:

- Small equipment footprint.

- High oil quality, shorter product oil extraction cycles.

- High refining production, lower auxiliary material consumption, meeting the requirements for deep product processing.

- This process requires continuous operation and is suitable for larger tonnage(>30ton), continuously operating business.

Different refining processes design can directly impact the purity, nutritional components, solvent residue levels, and more of sunflower oil. Therefore, it is advisable to collaborate with experienced manufacturers and choose suitable and advanced refining processes.

Vital Strategies: Maximizing Efficiency in Sunflower Seed Oil Refining

Refined Sunflower Oil Production Process

The first step in refining control is to precisely manage temperature and time in each stage of production line. The temperature settings in steps like decolorization and deacidification must be precise to ensure that no unnecessary impact is imposed on the oil's structure and quality. Additionally, accurate time control contributes to achieving optimal results, ensuring that oil quality is not compromised due to excessively long or short processing times. So, this necessitates a well-thought-out design of the refining process and the utilization of advanced technology to build and make the necessary equipment for precise temperature and time control.

In addition to temperature and time, the use of additives also requires careful control. The type and quantity of additives directly affect the flavor, stability, and color of sunflower oil. Proper use of additives and accurate measurement ensure that the characteristics of sunflower oil are preserved, unaffected by external factors. This entails having precise control over the addition of additives at the refining plant using specialized machinery to start the process, ensuring the desired product quality.

Finally, refining control also involves the precise calibration of instruments and equipment. Correct setup and calibration of automated machinery ensure the accuracy of parameter measurements and production process stability. These equipment provide crucial support throughout the refining process to make each batch of sunflower oil meeting consistent high-quality standards.

Parameter and Indexe in Sunflower Oil Refining Process

| Steps | Parameter and Method | Index |

|---|---|---|

| Degumming |

Temperature:50-80℃ Time:15-30min Phosphoric Acid Dosage:0.05%-0.2% of Oil Weight |

Phosphorus Content :50–200 ppm Moisture <0.1% Acetone Insolubility(AI)65%-70% |

| Decolorization |

Decolorizing Dosage:10 kg / 100 kg sunflower oil Temperature:60°C±2°C Time:30 minutes |

Color Value: 25 (Lovibond units) Transparency: 98% Impurity Content: < 0.1 |

| Deacidification |

Acid Value Test: 0.2% (initial value) Type and Quantity of Alkali: Alkaline solution, 0.6% Temperature: 50°C±1°C |

Final Acid Value: 0.05% pH Value: 7.0 Oxide Content: < 0.2% |

| Deodorization |

Odor Detection: 10 ppb (initial value) Steam Injection Rate: 50 kg/h Temperature: 110°C±3°C |

Odor Concentration: 2 ppb Oxide Content: < 0.1% Deodorant Dosage: 300 ppm |

| Dewaxing |

Time:6-8h Temperature:10℃-15℃ |

Dewaxing Rate:95% |

| Filtration |

Filter Mesh Fineness: 10 micrometers Filtration Rate: ≤ 300 L/h Equipment Cleaning: Clean the filter every 10 batches of oil |

Impurity Particle Count: < 10 particles/ml Clarity: 98% |

| Additive |

Type of Additive: Vitamin E Mixing Method: Thoroughly mix vitamin E at 30°C |

Additive Dosage: 200 ppm |

| Automation Control | Automatically adjust heating power, valve opening, and flow control valve |

Temperature: 80°C Pressure: 0.3 MPa Flow Rate: 50 L/h |

(This is for your reference only.)

The rational design of the refining process is crucial for the development and competitiveness of investing sunflower oil refining process plant. It can eliminate bottlenecks and waste in the production process, enhance refining quality and production efficiency, reduce costs, thereby increasing output and profits. Additionally, it can optimize the production process by incorporating advanced machine technology, reduce product defects and variations, improve product quality and stability. Furthermore, it can also reduce environmental pollution and resource consumption, promote sustainability, and align with social responsibility and business image.

| Projects | Country |

|---|---|

| 1TPD Mini Olive Oil Refinery Plant | Peru |

| 3TPD Fish Oil Refinery Plant | Bangaladesh |

| 10TPD Soyabean Oil Refinery Plant | Mauritius |

| 20TPD Coconut Oil Refining Factory | Philippines |

| 30TPD Cotton Oil Refining Plant | Afghanistan |

| 10TPD Grape Seed Oil Refining Plant | China |

ABC Machinery's batch, semi-continuous, and continuous refining processes are designed to meet the refining needs of various tonnages. Through years of technological innovation, we have not only reduced costs compared to our competitors by minimizing auxiliary materials and energy consumption but also significantly improved the related production equipment, resulting in oil products of higher quality than those of our competitors. We are committed to providing you with comprehensive equipment and technical support through our professional services. Please feel free to contact us at any time.

Build Your Future!

Build Your Future!