This 10TPD soyabean oil refinery plant machinery was ordered by our client in Mauritius. It is a turnkey project including factory layout, equipment manufacturing, onsite installing and debugging. (Related Project: 20TPD Small Edible Oil Refinery Project in the Philippines)

Soyabean Oil Refinery Plant Machinery Photos

Photos about this project are listed below. Feel free to contact us if need more details of our refining machinery, and you are also welcome to tell us your plan and let us help you start your own cooking oil processing factory.

Crude Soyabean Oil Deodorization and Decolorization

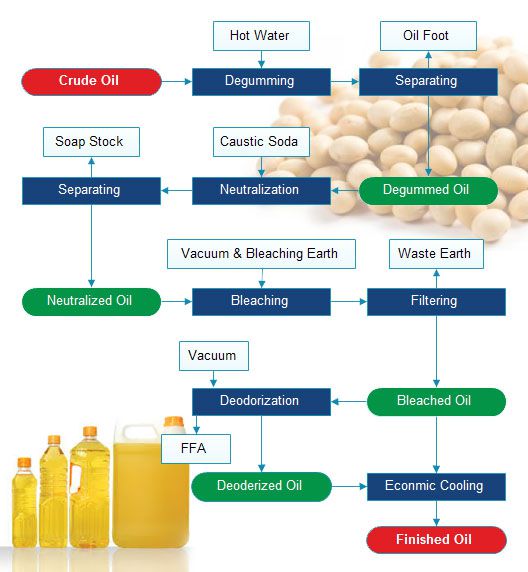

The industrial process for the deodorization and decolorization of soyabean oil occurs in the subsequent stages: Pretreatment, Degumming, Neutralization, Water Washing, Bleaching, and Deodorization.

Soyabean Oil Refining Process

- Pretreatment

At this stage, water is the main degumming element. There is a 650 p.p.m phosphorous content, which represents 1.95% of phospholipids. It's then pumped at a speed of 30, 000 pounds per hour through a line. It's measured through the line with a flow controller as it flows at a speed of 300 pounds/hr. The estimation of wet gums is 45% phospholipids, 22% soybean oil, and 33% water. The wet gum oil is then processed further to turn it into commercial lecithin. Based on dry weight, this results in 98% of degummed oil. (Related Product: Oilseeds Pretreatment Machines)

- Degumming

This is a process that omits assorted mucilaginous products, essentially albuminoid substances, phospholipids, or protein from the unrefined vegetable oil. These products are the reason behind the bitter, and unbearable aroma and flavor of the raw oil. The degumming stage involves mixing the unrefined vegetable oil with an organic acid like acetic acid or phosphoric acid, and a little water. The gums that are derived from this stage contain carbohydrates, phospholipids, metals, proteins, soaps, small parts of free fatty acids, and water.

- Bleaching

Bleaching is done by either Activated Carbon reagent or Fuller Earth. This diminishes the free fatty acid concentration and phospholipids of the degummed oil enough to end up with a product that is sufficient, owing to the removal of other impurities like peroxide compounds. Because of the enhanced refining procedure, two traditional refining stages like water treatment and neutralization are not necessary.

- Neutralization

This implies the neutralization of fatty acids by mixing in caustic soda and then separating the ensuing soapstock from the oil. Neutralization is done by treating the oil with an aqueous mixture of sodium hydroxide or alternative concentrated alkaline agents.

- Deodorization

In the course of this stage, the vegetable oil is passed through steam while under a vacuum and high temperature. The procedure may last from one and a half hours to 7 hours. The acid level of the oil is significantly decreased, its color improved, and its flavor and smell become bearable.

Unrefined soybean oil has assorted degrees of impurities like mucins, phosphatides, dyes, free fatty acids, and other ingredients that affect its color and smell. These impurities can be eliminated by various processes based on absorption. Here, two absorbing agents are taken into account: Activated Carbon and Fuller Earth.

Build Your Future!

Build Your Future!