Invest Sunflower Seed Pretreatment Production Line

Why is Pretreatment Essential in Sunflower Oil Production Process?

Pretreatment during sunflower oil production process refers to a series of physical, chemical, or biological steps performed on oilseeds before they are fed into the oil extraction machine. These steps aim to optimize the extraction process, enhance oil production yield and quality. The purpose of pretreatment is to mitigate adverse factors, improve oilseed extractability, protect oil extraction machine, and elevate the quality and stability of the sunflower oil. Specific steps may vary based on the type of oilseeds and extraction techniques employed. Common pretreatment steps in sunflower oil production process include cleaning, drying, dehulling, flaking, and cooking.

Quality Criteria for Crude Sunflower Oil

| Category | Quality Standards |

|---|---|

| Flavor and Aroma | Possesses the inherent scent and flavor of sunflower oil devoid of any undesirable odors. |

| Moisture and Impurities (%) ≤ | 0.20 |

| Insoluble Impurities (%) ≤ | 0.20 |

| Acid Value (mg KOH/g) ≤ | 4.0 |

| Peroxide Value (mmol/kg) ≤ | 7.5 |

| Solvent Residue (mg/kg) ≤ | 100 |

Steps — Pretreatment in Sunflower Oil Production Process

Sunflower Seeds Dehulling Machine

- Cleaning and Drying

Sunflower seeds obtained by sunflower oil production processing plants often contain various impurities, such as dust, straw, sand, metal, and hemp fibers. If not removed, these impurities can not only disrupt normal production but also affect the quality of oil and cake. Hence, in sunflower oil production process, you should buy a cost-effective cleaning machine within your budget to remove these impurities beforehand. There are various methods for impurity separation, including wind separation, sieving, density separation, and magnetic separation. Since the raw material for sunflower oil manufacturing process needs to be hulled by a dehulling machine, individual seeds with high moisture content need to be dried to an appropriate moisture level. This facilitates the separation of kernel and husk.

- Dehulling

Prior to sunflower seeds entered oil extraction machine, they require dehulling to reduce the adsorption of oil by the shell. This enhances the efficiency of sunflower oil extraction machine, promotes the crushing of sunflower kernels, and improves the quality of crude sunflower oil and cake. During dehulling, efforts should be made to prevent kernel breakage and maintain kernel integrity. Additionally, when using an oil making machine to press the sunflower seed kernels, a certain amount of shell is beneficial for creating extrusion pressure and maintaining unobstructed oil pathways. Therefore, you should find a reliable euqipment supplier and manufacturer to buy a low-price and high-quality dehuller.(Line to: Sunflower Seed Dehulling Machine for Sale)

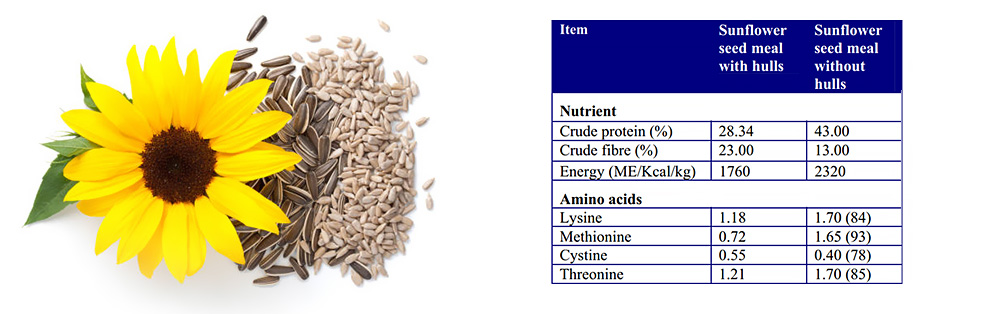

In-Shell and Shelled Sunflower Seed Kernel

(Note: Figures in parentheses indicate percentage digestion coefficients of respective amino acids.)

- Flaking

Flaking involves pressing sunflower kernels into thin flakes using a flaking machine. This aims to disrupt the cellular structure of the kernels, shorten the oil pathway, and create favorable conditions for subsequent cooking. It also enhances the efficiency of extraction. Flakes should be thin, even, with minimal powder, no visible oil, and soft to the touch. Generally, the thickness of sunflower kernel flakes should not exceed 0.5 millimeters.

- Cooking

Cooking induces specific physicochemical changes and alter the internal structure of the sunflower seed kernels, transforming raw flakes into cooked flakes. The effectiveness of cooking has a direct impact on the entire sunflower oil production process, oil yield, and the quality of sunflower oil and cake. Based on experience, the moisture content of steamed flakes is typically 8% to 10%, with a steaming temperature of 95 to 100°C. Using a vertical cooking pot, the moisture content of the discharged flakes is 6% to 7%, and the discharge temperature is 110°C. The recommended cooking time is generally around 1 hour.

ABC Machinery is a leading supplier specialized in providing sunflower seed oil pretreatment production line design and equipment at factory price. We are committed to delivering cost-effective and reliable machinery and comprehensive solutions to help our customers achieve outstanding results in the sunflower oil production process. Whether you have any questions about our equipments or are interested in our technology and services, we are more than happy to offer free assistance and consultation.

Quality Control Measures for Sunflower Seed Pretreatment Production Process

Sunflower Seeds for Oil Extraction

Pretreatment is the first line of defense to ensure the quality of sunflower oil, while quality control is the key to continuously safeguard its quality. From cleaning, dehulling, flaking to cooking, each step lays a solid foundation for subsequent extraction and processing. And throughout the entire process, strict quality control measures are indispensable.

- Raw Material Quality: Buying high-quality, mold-free, and odor-free sunflower seeds within your budget as raw materials. Conduct visual inspection to ensure that the color, shape, and size of the sunflower seeds meet the standards.

- Cleaning Treatment: During the cleaning process, ensure thorough removal of impurities, dust, and stones from the surface of sunflower seeds. Buying appropriate cleaning machine and screens, and perform regular equipment maintenance to maintain cleanliness.

- Dehulling Control: During the dehulling process, pay attention to controlling the proportion of shell removal from sunflower seeds. Excessive dehulling may result in seed damage and nutrient loss, while insufficient dehulling can affect the efficiency of subsequent oil extraction and processing.

- Drying Process: Ensure proper temperature and time control during the drying of sunflower seeds. Excessive temperature and prolonged drying time may affect the quality and oil properties of sunflower seeds.

- Sorting Stage: During the sorting process, rigorously inspect the integrity and color of sunflower seed, and remove deteriorated, discolored, or damaged seeds. Ensure that only high-quality sunflower seeds enter the next stage of processing.

| Factors | Target Ranges |

|---|---|

| Temperature | 50-70℃ |

| Humidity | 8-10% |

| Cracking Rate | 40-60% |

| Cleaning Time | 15-30 minutes |

| Dehulling Rate | Above 95% |

| Cooking Temperature | 110-120℃ |

| Cooking Time | 30-40 minutes |

| Drying Temperature | 60-70℃ |

| Drying Time | 4-6h |

- Temperature and Humidity Control: Appropriate temperature promotes the flow and separation of oil, while appropriate humidity improves oil extraction performance.

- Standard Operating Procedures: Train staff to ensure that they follow standard operating procedures for each pre-processing step. Build standard operating procedures (SOPs) to ensure consistent quality.

- Records and Traceability: Start to record key parameters of each pre-processing step, including time, temperature, humidity, operator, etc. This helps trace the root causes of issues.

- Quality Testing: Build quality testing at critical steps, such as moisture content, dehulling rate, integrity rate, etc. Ensure that the product meets the specified standards.

- Continuous Improvement: You should build a quality evaluation system, then regularly conduct assessments, analyze data, and identify improvement opportunities. Continuously optimize the pre-processing process based on feedback and data.

If you are interested in edible oil extraction equipment and services provided by ABC Machinery, please contact us immediately. Our team is dedicated to addressing your concerns, providing detailed information, and assisting you in selecting the BEST solution that suits your needs.

Build Your Future!

Build Your Future!