Sunflower Oil Porduction: Expeller Press vs. Solvent Extraction

Sunflower seed oil boasts an impressive content of over 95% unsaturated fatty acids, with a remarkable absorption rate of over 96% within the human body. Packed with nutrients like vitamin E, carotenoids, and minerals such as magnesium, phosphorus, sodium, calcium, iron, potassium, and zinc, it has rightfully earned its reputation as a "healthful edible oil." But how is this sunflower seed oil with such exceptional nutritional value pressed?

| Organic Composition Chart of 100g Sunflower Oil | ||||||

|---|---|---|---|---|---|---|

| Calories/KJ | Fat/g | Saturated Fat/g | Monounsaturated Fat/g | Polyunsaturated Fat/g | Sodium/mg | Vitamin E/mg |

| 3700 | 100 | 13 | 21 | 66 | 2.8 | 20-70 |

Expeller Pressed Sunflower Oil vs. Solvent Extraction

Common sunflower seed oil extraction processes can be categorized into two methods: expeller pressed sunflower oil and solvent extraction. Next, we will briefly introduce these two methods of sunflower oil production.

Sunflower Oil Press & Extraction Machinery for Sale

Expeller Pressed Sunflower Oil

What is expeller pressed sunflower oil? This is a mechanical method (An oil press machine) used for extracting oil, suitable for both large-scale and small-scale production of sunflower oil. It can be used for the initial processing of sunflower seeds to extract oil and leave behind oil cake. Sunflower oil can be pressed using either cold-pressed or hot-pressed methods.

Cold pressing sunflower oil involves oil extraction through physical mechanical means without heating, or at low temperatures (<40°C). This entire process occurs at a low temperature, resulting in a lower oil yield but preserving the authentic taste of the seeds.

Hot pressing sunflower oil involves pre-processing sunflower seeds through steps such as roasting or cooking at high-temperature (60°C to 120°C), enhancing the oil's fragrance and oxidative stability. This effectively breaks down sunflower seed structure for pressing.

Hot pressing results in a more ideal oil yield, extracting a larger portion of the oil content, but high temperatures can lead to nutrient loss. Cold pressing, on the other hand, preserves the nutritional components of the oil, making cold pressing popular in small and medium-sized sunflower oil mills. Some home-based workshops also employ the cold-pressed method to produce edible oil. Additionally, the price of cold-pressed sunflower oil tends to be slightly higher than hot-pressed oil. Hot pressing is generally suitable for large-scale oil extraction plant. (Read More: Hot-Sale Sunflower Oil Pressing Machine)

Solvent Extraction Sunflower Oil

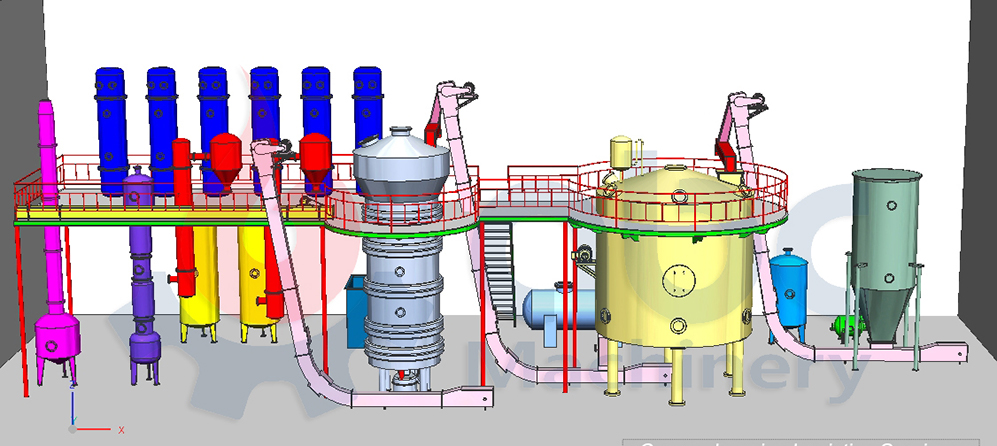

80T/D Atmospheric Extraction Plant Process Flow

Solvent extraction is a method of extracting sunflower oil by utilizing chemical solvents. It is commonly employed in large-scale industrial production and allows for efficient extraction of substantial quantities of sunflower oil.

Pre-pressing extraction involves initially pressing the oilseeds to extract most of the oil content. Then sunflower seed cake after pressing is then subjected to solvent extraction to further extract the residual oil trapped in the cake, thus increasing the oil yield. The solvent extraction process can reduce the residual oil in the cake to less than 1%. Additionally, the operating temperatures in various steps of the solvent extraction method are relatively low, minimizing denaturation of proteins in the cake. As a result, the quality of the cake is improved, and substances like proteins are better preserved. This makes the cake suitable for protein extraction and food processing applications, enhancing the value of sunflower seed cake. (Read More: Solvent Extraction Mahcinery for Sale)

The method of expeller-pressed sunflower seed oil is popular with investors due to its relatively lower investment costs and the adaptable scale of oil production it offers. This approach allows for the construction of both full-scale sunflower oil plant and small sunflower oil mills, making it more accessible to most investors. Additionally, sunflower seeds have a high oil content, and most of the oil within the kernels can be efficiently pressed, which meets the needs of most investors. While the solvent extraction method has a lower residual oil rate, it might entail a significant solvent consumption, resulting in elevated production costs for sunflower oil processing plants. Consequently, many oil production plants are inclined to opt for the method of expeller-pressed sunflower oil, achieving the desired production outcomes.

Pros and Cons of Expeller-Pressed Sunflower Seed Oil and Solvent Extraction

| Expeller-Pressed Sunflower Seed Oil | Solvent Extraction Sunflower Oil | |

|---|---|---|

|

Advantages |

Natural and Pure Retains Nutrients Versatile Application |

High Production Yield Stable Oil Quality |

| Disadvantages |

Low Production Yield Dependence on Raw Material Quality |

Chemical Residue Nutrient Loss |

How to Improve Sunflower Seed Oil Extraction Rate?

Factors - Improve Sunflower Oil Extraction Rate

Increasing oil extraction rate of sunflower seeds is a critical concern for many sunflower oil processing businesses. A higher oil extraction rate translates to more profits and greater economic value for investors. ABC Machinery's engineering team, with its rich experience in equipment design, installation, and commissioning, has summarized four aspects to consider when aiming to boost sunflower seed oil extraction rate.

- Quality of Sunflower Seed

The quality of sunflower seed directly affects the oil extraction rate. Choose sunflower seeds with plump kernels and high oil content. Additionally, high impurity levels in the raw material can also affect oil extraction rate, so it's essential to use a cleaning machine to remove dust, stones, and other impurities from the sunflower seeds. Our engineers recommend building sunflower seed pretreatment production line to prepare the sunflower seed material for extraction.

- Production Machine for Sunflower Seed Oil

The higher the configuration of sunflower seed oil production machine, the lower the oil loss during the production process, resulting in a faster oil extraction rate. If you have sufficient capital and a large processing capacity, you can choose a complete sunflower seed oil production line with high automation, minimizing oil losses and producing high-quality oil. If your budget is limited, you can choose complementary cleaning machines and cooking pots alongside the oil press machine to accelerate oil extraction.

- Production Process for Sunflower Seed Oil

Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%. It's worth noting that solvent extraction machine is costlier. If your daily processing capacity is less than 20 tons, our engineers recommend using the pressing method, which is cost-effective and suitable for daily production needs. Of course, ABC Machinery's engineers can recommend and design suitable equipment processing solutions based on your production scale, processing capacity, and budget.

- Standard Operating Procedures During Sunflower Seed Oil Production

To increase sunflower seed oil extraction rate, following standardized operating procedures during production is crucial. Deviations in operating time, temperature, or feed rate, whether too fast or too slow, can impact the oil yield during sunflower seed oil production. However, you need not worry about this, as ABC Machinery has its own team of engineers and equipment manufacturing experts. ABC Machinery can design plant layouts, provide equipment installation and technical commissioning services, and conduct systematic training for workers to ensure standardized operations and enhance sunflower seed oil extraction rate.

ABC Machinery not only boasts extensive experience but also offers a diverse range of sunflower oil pressing methods, equipment, and technology. Whether you're seeking cold pressing, hot pressing, solvent extraction, or any other oil extraction technique, we have the capability to provide you with precise and efficient solutions, ensuring you obtain high-quality oil products while maximizing both yield and efficiency. Contact us now! We will provide you with free consultation and services.

Build Your Future!

Build Your Future!