This is a soya bean oil mill project set up in Ghana, including 25TPD soya bean oil extraction line and 5TPD crude oil refinery line. (Related Project: 100TPD Turnkey Soybean Oil Mill Project in Zambia)

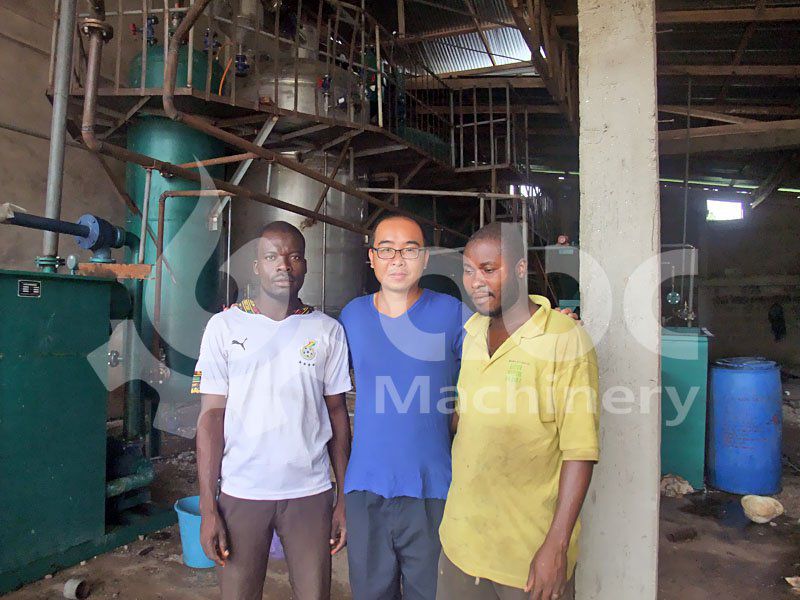

Soya Bean Oil Mill Plant Phots

The following photos show the onsite situation. Welcome contact us if you want to know more equipment details and cost list. We are always ready to serve you.

Process of Medium Scale Soya Bean Oil Mill

Soybean oil is a natural vegetable oil extracted from soybean crop, planted in very many countries across the world like Argentina, Korea, China, Tanzania and Canada. It is a widely used food industry vegetable oil that as significantly low levels of fat, way below 3 percent. The best advantage of this soybean oils is that they are cheap and healthy, you rarely can find such healthy products at such a low cost. (Related Product: Mini Soybean Oil Processing Plant for 2~10 ton/h production)

There are essentially two different methods and procedures used in the soybean oil production industry, hot pressing and cold pressing. Let us take an in depth look at this two processes.

Hot Pressing

- This stage essentially contains seven key processes at the soybean oil mill: cleaning, crushing, swelling, extruding, drying, oil pressing and filtering. (Recommend Product: Mini Type Refinery Plant)

- After harvesting there tends to be a lot of impurities mixed up with the soybeans. To get completely rid of dirt and other unwanted substances, soybean is screened thoroughly with a 12 mesh inch screen, to the point of less than 0.1% impurity level content.

- The soybean is then crushed inside a crusher with a 1.5 mesh hole and later extruded to ensure its moisture content is around 15%.

- Soya bean extruding is essential and done because of this two major reasons. The first being to increase surface area of bean, which in turn increases oil outlet area, reducing the distance when the oil leaves soy embryo. The second being to facilitate easy oil flow from intracellular by destroying the soybeans cell tissues The soybeans are then transferred to a plate dryer for drying.

- The drying process of soya bean oil plant takes a little bit of time, until the moisture is within 7 to 8 percent and a temperature of between 100 to 110 degrees.

- After this the soy beans are pressed in a soybean oil expeller press using a cake thickness of about 1 to 1.5 mm.

Build Your Future!

Build Your Future!