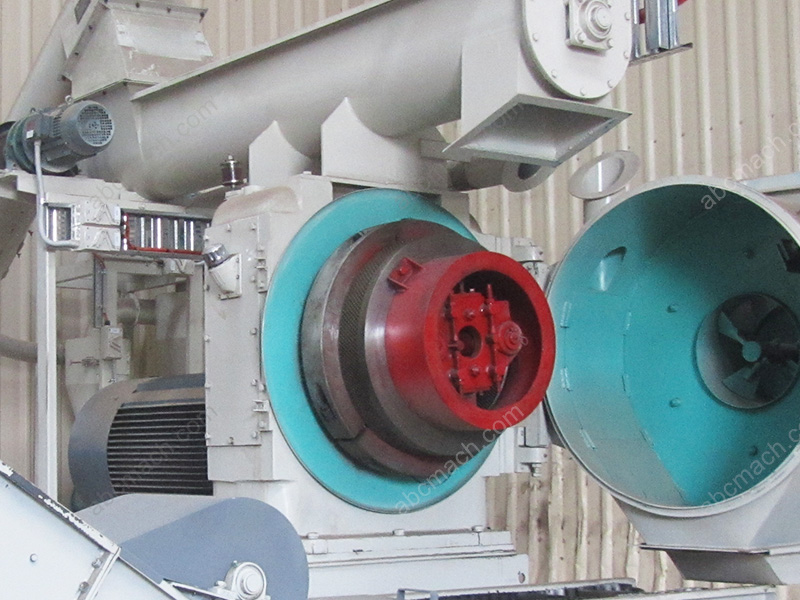

Vertical pellet mill is a new generation of biomass pellet making machine absorbing internationally latest pelletizing technology. Compared to traditional ring die pellet machine, it has many superiorities in terms of perfermance and efficiency due to great improvements in structure.

- Independent oil pump lubrication system allows automatically oiled at pinch roller;

- High automaticity and no need the specific people to look after the machine;

- Adopt external circulation cooling system for main transmission box and transmission gear oil;

- Improved main shaft ensures much longer service life of main shaft bearing, greatly reducing maintenance cost;

It is the preferred model in the biomass densifying or wood pelletizing industry.

Vertical ring die pellet machine is the major equipment for biomass pellet production and is suitable for the settting up of complete biomass pellet plant, from small scale to large scale.

| Model | VPM508-I | VPM508-II | VPM510 | VPM630 | VPM660 |

|---|---|---|---|---|---|

| Output designed (kg/h) | 700~1000 | 1000~1500 | 1500~2000 | 2000~2500 | 2500~3000 |

| Power (kw) | 55 | 75 | 90~110 | 132 | 160 |

| Dimensions (mm) | 2133*920*1389 | 2400*1300*1800 | 1800*1100*1700 | 1800*1100*1700 | 2590*1690*1890 |

| Weight (kg) | 2586 | 2908 | 3780 | 5600 | 7500 |

| Die inner diameter (mm) | Ø508 | Ø508 | Ø510 | Ø630 | Ø660 |

| Pellet diameter (mm) | ¢8~¢9 | ¢8~¢9 | ¢8~¢9 | ¢8~¢12 | ¢8~¢12 |

| Pellet forming rate | 98% | 98% | 98% | 98% | 98% |

| Pellet length (mm) | 10~50 | 10~50 | 10~50 | 10~50 | 10~50 |

| Moisture of raw material | 13~17% | 13~17% | 13~20% | 13~20% | 13~20% |

Vertical Ring Die Pellet Machine

Usually, dies of ring die pellet machine is installed vertically. But, dies of vertical ring die pellet mill are designed to place in horizontal direction, then raw materials are entered into pellet machine from top to bottom. So, the die is stationary and the pellet machine runs more smoothly.

When working, the pressure rollers rotate to produce centrifugal force on the material, which results in a more even distribution of material, no arching and is easy for heat dissipation. From the view of pellet production and cost control, vertical ring die pellet mill will be the optimal choice for more and more people who have ambitions in biomass fuel industry due to its excellent advantages. Just check the essential points of our newly developed vertical ring die pellet mill.

Advanced Cooling System & Independent Lubrication System

This part is very necessary and important since circulating cooling can keep the lubricating effect effectively.

Lubrication for Both Transmission Gearbox & Main Drive Shaft

- Gearbox Lubrication System: Oil is injected once per shift throughout the life of the roller.

- Main Drive Shaft Lubrication System: Using diluted oil for the circulating lubricating of Main Shaft separately, which can ensure fully lubricate while effectively prevent grease from aging due to high temperature, thus protecting the spindle and spindle bearing and extending the service life.

- Various parts of gear lubricants: Forced cooling the external of the gearbox, Circulate to the inside of the gearbox, greatly reduce the temperature rise of the gear oil, thereby extending the bearing life and the life of the gear.

Our vertical wood pellet machine adopts External Circulation Cooling System for main transmission box and transmission gear oil: External circulation cooling (air cooling or water cooling selection, according to the use environment) would reduce the working temperature of the gear oil, so that its normal working temperature is 40-50 °C.

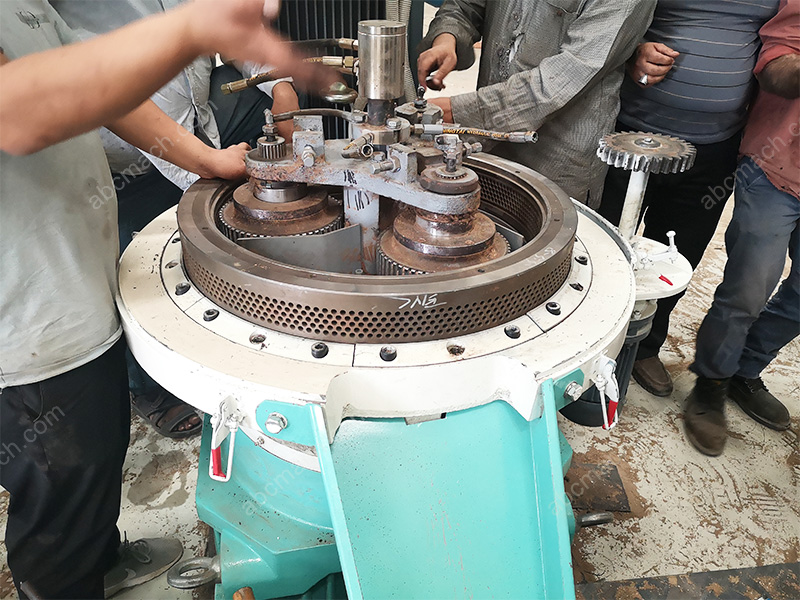

Adopt Gear Transmission Mode

- The whole machine adopts parallel helical gear transmission and has good toothability.

- Hardened bevel gear is used in the gearbox of our vertical wood pellet mill, the tooth surface is widened, the modulus is increased, the gear overlap ratio is big, the load of each pair of gears is reduced, the bearing capacity of the gear is improved, and the gear strength of the conventional gearbox is strengthened 5-10 times.

- The failure rate is lower than that of the traditional reducer, which greatly reduces the maintenance cost.

Features of the Gear inside Our Pellet Mill

- Gearbox adopts triple reduction transmission:

Transmission: 1:18 1:16 1:20 for optioning.

Each stage of gear is selected according to the speed of operation and the level of torque. Involute modulus and number of teeth for more efficient transmission.

- Each segment of gear adopts high-quality alloy steel carburizing and quenching technology, grinding gear processing to ensure the accuracy of gear transmission.

- Using FAG high quality bearing to assembly to keep more precise and more reasonable.

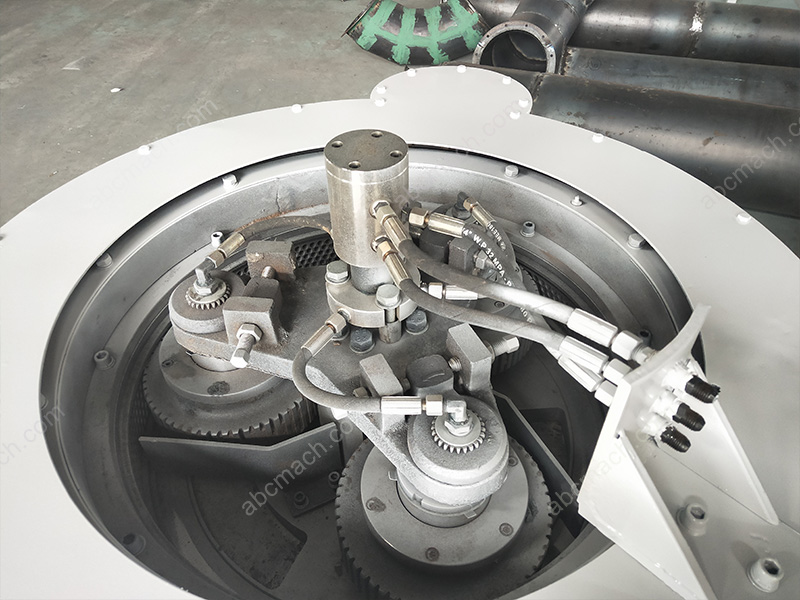

Adopt 3-Roller Pressing Structure

The 3-rollers, designed according to the three-point one side principle, are evenly distributed in a positive triangle in the working area of the die, which ensures smooth running when the machine is working; Compared to 2-rollers structure, ring die pellet machine with 3-rollers has higher output. And the die heats up quickly, which makes the pellets forming better.

3-Rollers Pressing Section

After the material enters the pressing chamber, it is pressed by 3-rollers. The 3-rollers structure ensures the stability of the pressed material, which is extruded into the ring die and then excluded from the die hole and made into the required length of pellets by the scraper mechanism.

Adjustable Feed Speed

During the startup process of the pellet press, the feeding speed can be adjusted according to the running current of the equipment, which increases the output and saves the electricity cost. Besides, It avoids problems such as stopping running due to the material feeding too fast.

Lower Wood Pellet Production Cost & Labor Cost

Complete Biomass Pellet Plant at Low Cost

Moreover, vertical ring die pellet machines which are designed with adjustable feed speed can also save labor in controling the electric control cabinet, especially for large scale commercial pellet plant or industral pellet production line which have multiple pellet making machines.

How Vertical Ring Die Pellet Mill Makes Wood Pellets?

Vertical ring die pellet machine, designed with 3-rollers, is manufactured by digesting and absorbing the experience of our domestic counterparts. It solves problems of traditional pellet machines, including low utilization ratio, large power consumption, high roller maintenance rate, tedious replacement, high maintenance cost etc;

Working Principlne of Vertical Ring Die Pellet Machine

Raw materials with a moisture content less than 20% enters the feeding winch through the inlet, and by adjusting the rotational speed of the feeding winch blades, a suitable material flow is obtained and then enters the pressing chamber for pelletizing. The motor of the feed winch consists of a three-phase asynchronous AC motor, a vortex clutch and a speed measuring motor, which is used in conjunction with the JZT controller.

Vertical Pellet Mill Starts Biomass Pellets Production Business

The output speed can be changed by means of the JDIA electromagnetic motor controller, so that the speed of the feeder strand is controlled between 12 and 50 revolutions per minute. The size of the feeder speed determines the output of the pellet machine, i.e. the speed of the feeder strand determines the current of the main motor. Therefore, by changing the speed of the feeder, the feeder delivery is effectively controlled to meet the pelleting capacity of the pressing chamber. As the pelleting capacity is influenced by a variety of factors such as the quality of the material, the size of the humidity, the difference in material and the change in voltage. So, when one of these factors occurs randomly, the feeder delivery should be changed at any time so that the wood pellet mill is always in normal working condition. The current of the main motor should not exceed its rated current. After the material enters the pressing chamber, it is pressed by 3-rollers pressing section, extruded into ring die, cut at required length by scraper.

Other Highlights of Our Vertical Ring Die Pellet Mill

- Specific Roller Assembly Structure: Specific roller assembly structure would eliminates the phenomenon of burning bearings. Under normal working conditions, it only needs to add grease 2-3 times per shift.

- Using Siemens-Bedford Motor:Y315M-4-V1-160KW vertical installing.

- Electrical Startup: Using soft startup on the electrical control based on the structure of gear transmission.

- Stainless Steel Ring Die: Customiz each ring die depend on each of our client's raw materials and requirements.

- Premium Quality: Its main parts are manufactured through teeming and overall forging, and the other components are manufactured by the production center with high precision and abrasive resistance.

- Safe and Efficient Design: Adopts variable-frequency and variable-speed motor for feeding raw materials, overload protection device, external discharging mechanism and lubricating system for oil pump.

- Custom-made Production: The ring die can be selected from¢8 to ¢10 to meet different production demands.

- Ideal Biomass Pellet Machine: It is featured with compact structure, elegant appearance, high production capacity, low electricity consumption, convenient operation and reliable working etc.

Biomass Materials Suitable for Vertical Ring Die Pellet Mill

- Wood Offcuts: wood chips, sawdust, poplar, date palm, bamboo, eucalyptus, twigs, trunks, bark, shredded palm, etc.

- Food and Vegetable Husks: straw, rice husk, sunflower seed husk, peanut husk, coffee husk, cassava residue, coconut husk, etc.

- Sludge, RDF waste derivatives, etc.

Build Your Future!

Build Your Future!